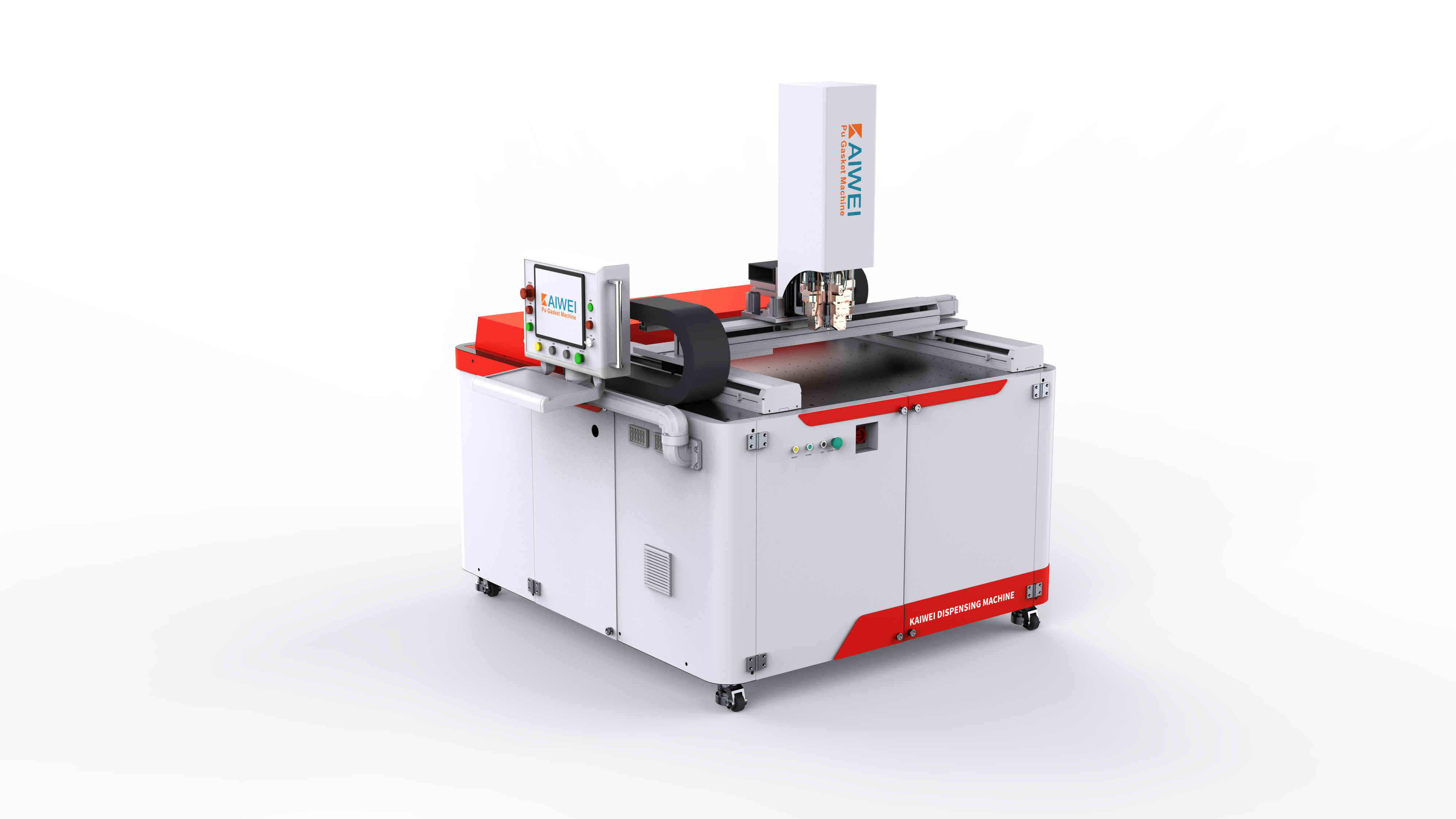

zařízení pro pěnové uzavírání na místě

Zařízení pro vytváření pěnových těsnění na místě představuje špičkové řešení pro automatizované dávkování pěny a těsnicí aplikace v různorodých výrobních prostředích. Toto specializované zařízení kombinuje přesné řídicí systémy s pokročilou technologií dávkování, čímž zajišťuje konzistentní a kvalitní pěnová těsnění pro automobilový, letecký a elektronický průmysl i průmyslové aplikace. Zařízení pro vytváření pěnových těsnění na místě pracuje pomocí sofistikovaných dávkovacích systémů, které přesně míchají vícesložkové pěnové materiály, čímž zajišťují optimální chemické reakce a rovnoměrnou expanzi pěny. Tyto systémy jsou vybaveny programovatelnými logickými regulátory, které řídí regulaci teploty, monitorování tlaku a úpravu toku s vynikající přesností. Zařízení obsahuje ohřívané hadice a dávkovací hlavy, které udržují optimální teplotu materiálu po celou dobu procesu aplikace, čímž zabraňují předčasnému vytvrzování a zajišťují hladký tok materiálu. Moderní zařízení pro vytváření pěnových těsnění na místě je vybaveno uživatelsky přívětivými dotykovými rozhraními, která umožňují operátorům ukládat více programových receptur, sledovat data o výkonu v reálném čase a provádět přesné úpravy během výrobních cyklů. Odolná konstrukce zahrnuje komponenty odolné proti korozi, navržené tak, aby zvládaly agresivní chemické směsi a zároveň zaručovaly dlouhodobou spolehlivost. Tato zařízení podporují různé typy pěn, včetně polyuretanu, silikonu a speciálních sloučenin vyvinutých pro konkrétní těsnicí požadavky. Modulární konstrukce zařízení umožňuje snadnou integraci do stávajících výrobních linek a zároveň splňuje požadavky na nestandardní nástroje a upínací zařízení. Pokročilá zařízení pro vytváření pěnových těsnění na místě jsou vybavena funkcemi kontroly kvality, jako je sledování hmotnosti, sledování doby vytvrzování a automatické systémy odmítnutí výrobků, čímž zajišťují stálou úroveň výstupních standardů. Environmentální ovládací prvky, včetně extrakce a uzavření par, zajišťují bezpečný provoz a splňují předpisy o bezpečnosti na pracovišti. Technologie podporuje jak ruční, tak plně automatické provozní režimy, čímž poskytuje flexibilitu pro různé objemy výroby a náročnost požadavků.