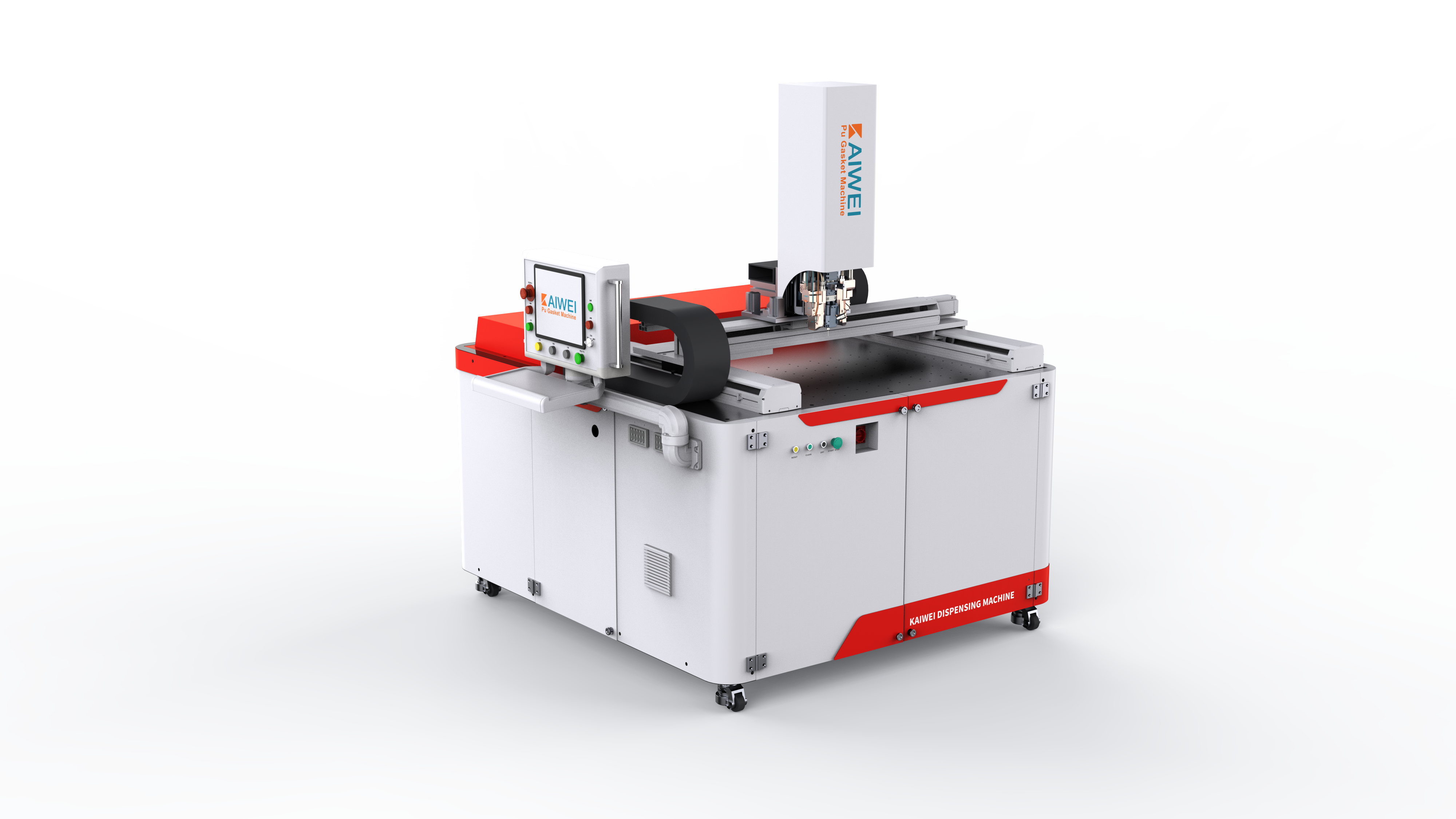

halpa pennan sulautuslaitevarusteet

Edullinen vaa'asealauksellinen laitteisto edustaa mullistavaa kehitystä pakkauksen teknologiassa, ja se on suunniteltu vastaamaan kasvaviin vaatimuksiin kustannustehokkaista tiivistysratkaisuista. Tämä monikäyttöinen koneisto toimii siten, että se ruiskuttaa laajenevaa vaa'akalvoa, joka luo ilmatiiviitä tiivisteitä erilaisten tuotteiden ja säiliöiden ympärille. Laitteen ensisijainen toiminto perustuu polyuretaanin tai muiden vaa'ayhdisteiden ruiskuttamiseen rakojen, liitosten ja aukkojen sisään, jolloin muodostuu vesitiivis ja säänsuojattu este. Nykyaikainen edullinen vaa'asealauksellinen laitteisto sisältää edistyneitä ruiskutusmekanismeja, jotka takaavat tarkan vaa'an sovelluksen ja samalla minimoivat hävikin. Tekniset ominaisuudet sisältävät säädettävät paineohjaimet, lämpötilansäätöjärjestelmät ja ohjelmoitavat ruiskutuskuviojärjestelmät, jotka sopeutuvat erilaisiin tiivistystarpeisiin. Nämä koneet sisältävät yleensä helppokäyttöisen käyttöliittymän digitaalisella näytöllä, jossa näkyvät toiminnalliset parametrit, kuten vaa'an tilavuus, painetasot ja kovettumisaika. Laitteisto tukee useita vaa'lajeja, mukaan lukien avosoluiset ja suljettusoluiset valmisteet, mikä mahdollistaa käyttäjien valita sopivat materiaalit tietyissä sovelluksissa. Teollisuuden sovellukset kattavat useita aloja, kuten rakennusteollisuuden, autoteollisuuden, kodinkoneiden valmistuksen ja pakkauksen alat. Rakennusyritykset käyttävät tätä edullista vaa'asealauksellista laitteistoa ikkunoiden ja ovien asennuksiin, kun taas autonvalmistajat käyttävät sitä äänieristykseen ja eristykseen. Laitteisto osoittautuu korvaamattomaksi kosteusesteiden, lämmöneristyksen ja värähtelyjen vaimentamisen ratkaisujen luomisessa. Valmistustilat hyötyvät sen kyvystä tiivistää elektroniset kotelot, ilmanvaihtojärjestelmien osat ja teollisuussäiliöt. Laitteisto soveltuu sekä manuaaliseen että automatisoituun käyttöön, mikä mahdollistaa sen integroinnin olemassa oleviin tuotantolinjoihin merkittäviä muutoksia tekemättä. Laadunvalvontatoiminnot takaavat johdonmukaisen vaa'an tiheyden ja adheesio-ominaisuudet, mikä johtaa luotettavaan tiivistystulokseen erilaisissa olosuhteissa ja lämpötilaväleissä.