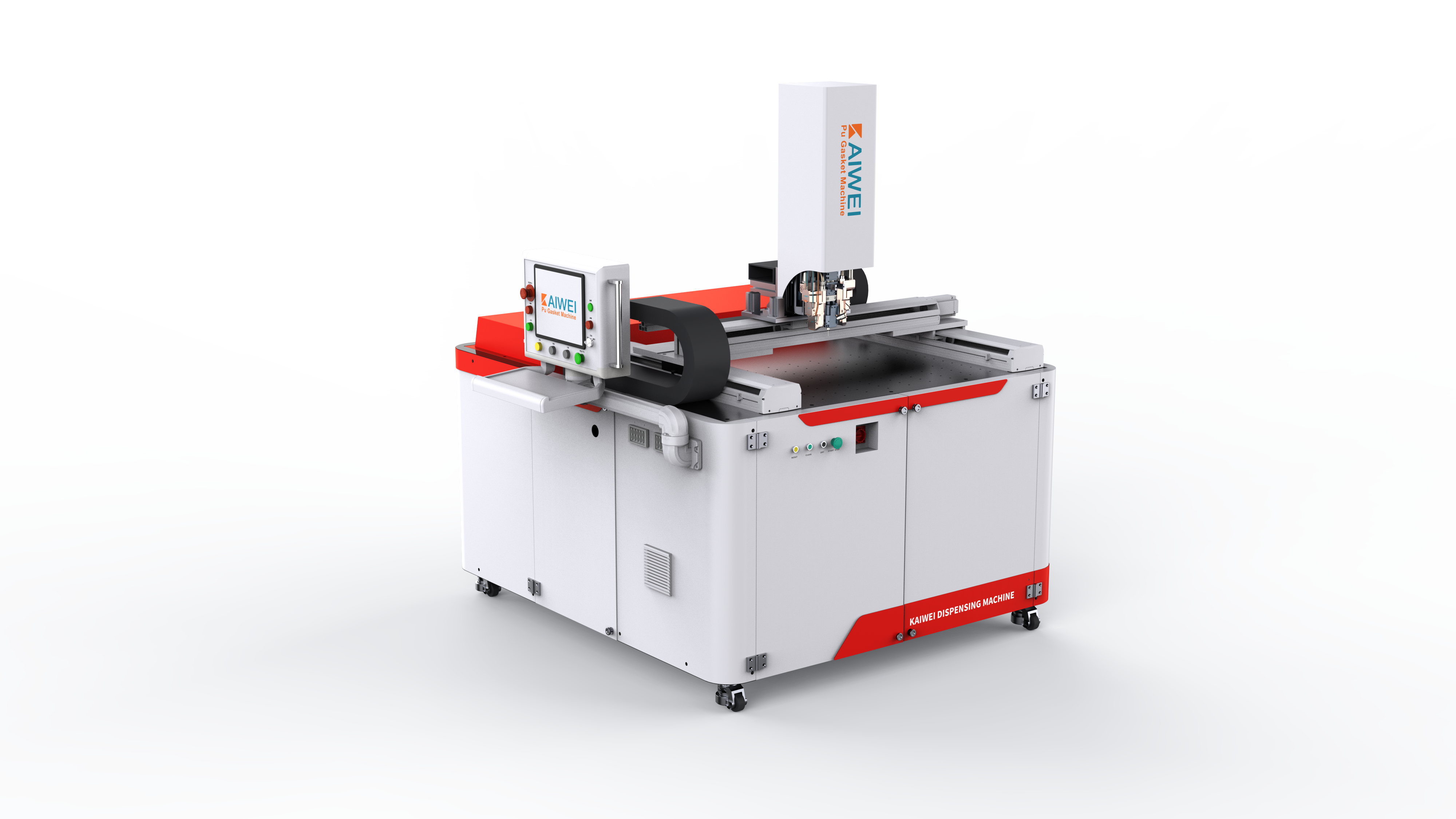

inexpensive foam sealing machine equipment

The inexpensive foam sealing machine equipment represents a revolutionary advancement in packaging technology, designed to meet the growing demands of businesses seeking cost-effective sealing solutions. This versatile machinery operates by dispensing expandable foam materials that create airtight seals around various products and containers. The primary function of this equipment involves injecting polyurethane or other foam compounds into gaps, joints, and openings to establish waterproof and weatherproof barriers. Modern inexpensive foam sealing machine equipment incorporates advanced dispensing mechanisms that ensure precise foam application while minimizing waste. The technological features include adjustable pressure controls, temperature regulation systems, and programmable dispensing patterns that accommodate different sealing requirements. These machines typically feature user-friendly interfaces with digital displays showing operational parameters such as foam volume, pressure levels, and curing times. The equipment supports various foam types including open-cell and closed-cell formulations, allowing operators to select appropriate materials based on specific application needs. Industrial applications span multiple sectors including construction, automotive manufacturing, appliance production, and packaging industries. Construction companies utilize this inexpensive foam sealing machine equipment for window and door installations, while automotive manufacturers employ it for soundproofing and insulation purposes. The equipment proves invaluable in creating moisture barriers, thermal insulation, and vibration dampening solutions. Manufacturing facilities benefit from its ability to seal electronic enclosures, HVAC components, and industrial containers. The machinery accommodates both manual and automated operations, enabling integration into existing production lines without significant modifications. Quality control features ensure consistent foam density and adhesion properties, resulting in reliable sealing performance across different environmental conditions and temperature ranges.