kiszámítható gumi zároló gép berendezés

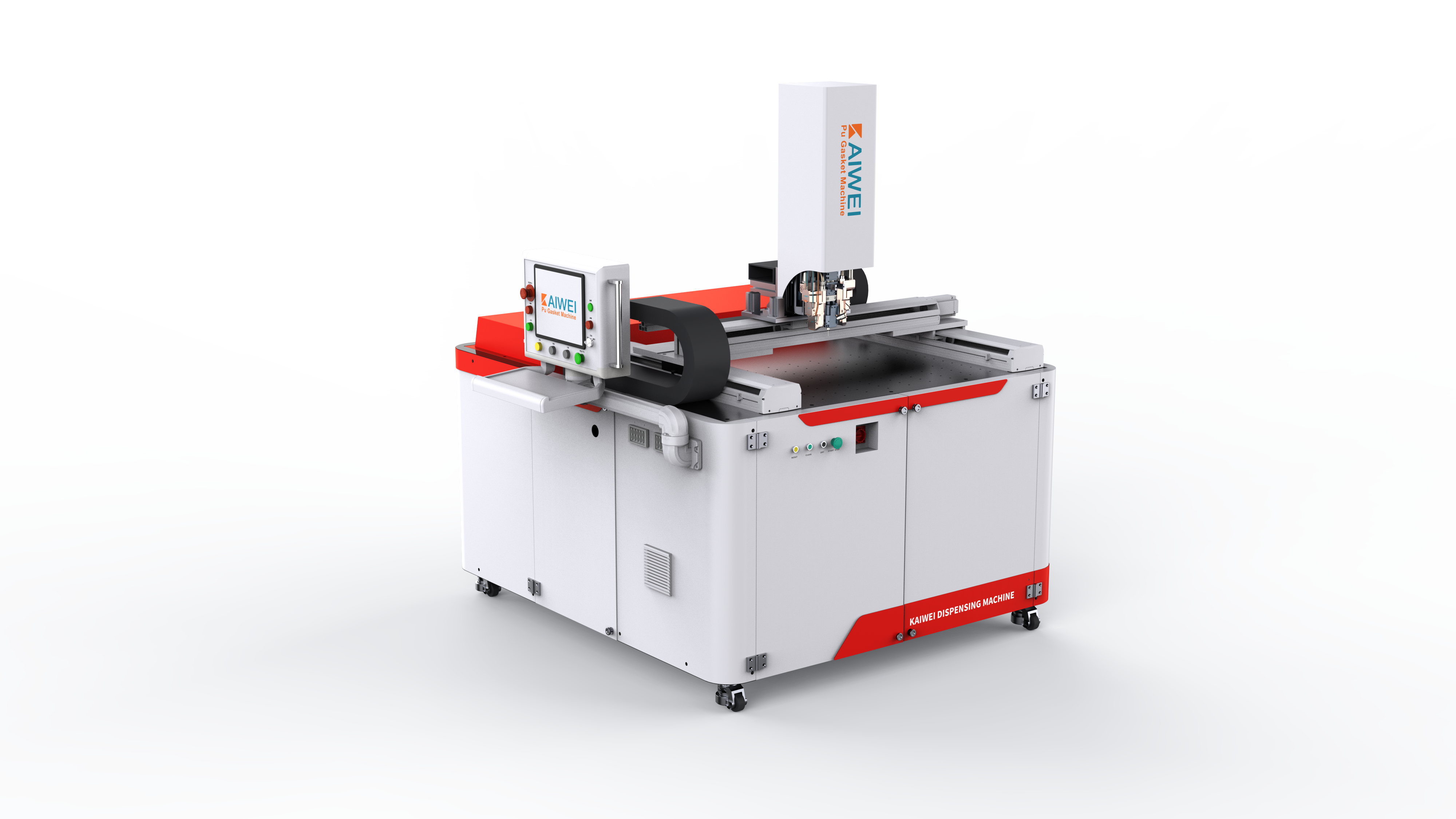

Az olcsó habtömítő gépek forradalmi fejlődést jelentenek a csomagolástechnológiában, amelyet azoknak a vállalkozásoknak a növekvő igényeinek kielégítésére terveztek, akik költséghatékony tömítési megoldásokat keresnek. Ez a sokoldalú berendezés tágulható habanyagok adagolásával működik, amelyek levegőt záró tömítést hoznak létre különféle termékek és edények körül. A berendezés fő funkciója poliuretán vagy más habvegyületek bejuttatása résekbe, illesztésekbe és nyílásokba víz- és időjárásálló határolórétegek kialakítása céljából. A modern, olcsó habtömítő gépek fejlett adagoló mechanizmusokat tartalmaznak, amelyek pontos habfelvitele mellett minimalizálják az anyagpazarlást. A technológiai jellemzők közé tartozik az állítható nyomásszabályozás, hőmérsékletszabályozó rendszerek és programozható adagolási minták, amelyek különböző tömítési igényekhez alkalmazkodnak. Ezek a gépek általában felhasználóbarát felülettel rendelkeznek digitális kijelzőkkel, amelyeken megjelennek az üzemeltetési paraméterek, mint például a hab mennyisége, a nyomásszintek és a száradási idők. A berendezés különféle habtípusok használatát támogatja, beleértve a nyitott és zárt sejtszerkezetű összetételeket is, lehetővé téve a kezelők számára, hogy az adott alkalmazási igények alapján megfelelő anyagot válasszanak. Az ipari alkalmazások több szektort is átfognak, ideértve az építőipart, a járműgyártást, a háztartási gépek gyártását és a csomagolóipart. Az építőipari vállalatok ablak- és ajtóbeszereléseknél használják ezt az olcsó habtömítő berendezést, míg az autógyártók hangszigetelési és hőszigetelési célokra alkalmazzák. A berendezés kiemelkedő fontosságú nedvességgátló, hőszigetelő és rezgéscsillapító megoldások készítésénél. A gyártóüzemek profitálnak abból, hogy elektronikai tokokat, légkondicionáló alkatrészeket és ipari edényeket tudnak vele lezárni. A gép kézi és automatizált működést egyaránt támogat, így integrálható meglévő gyártósorokba jelentős módosítások nélkül. A minőségellenőrzési funkciók biztosítják a hab sűrűségének és tapadási tulajdonságainak állandóságát, így megbízható tömítési teljesítményt eredményeznek különböző környezeti feltételek és hőmérsékleti tartományok mellett.