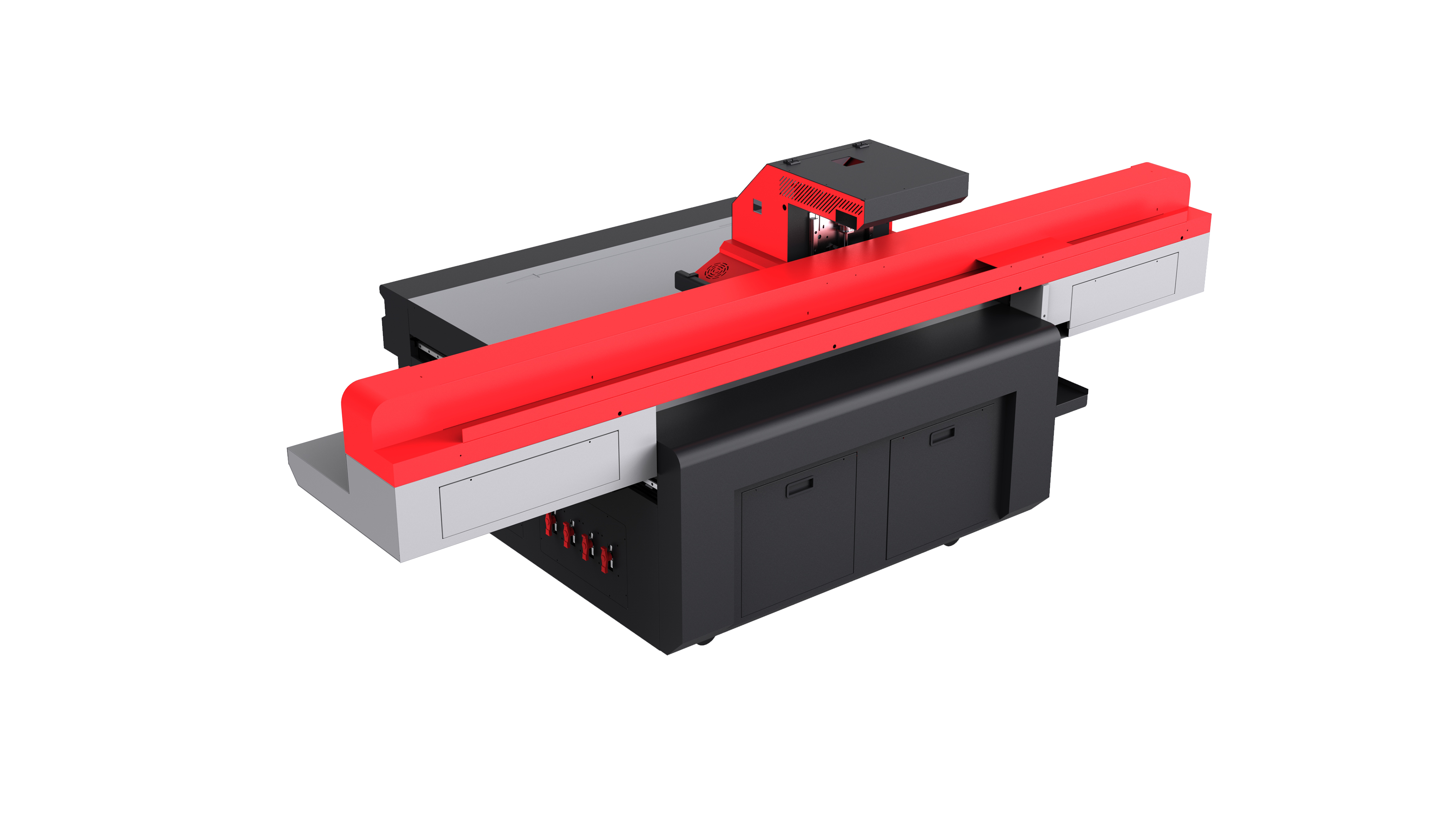

Versatilitas Luar Biasa di Berbagai Pilihan Substrat Tanpa Batas

Printer digital uv murah menunjukkan fleksibilitas luar biasa dengan berhasil mencetak pada berbagai macam bahan tanpa memerlukan perlakuan khusus, pelapisan, atau langkah pra-pemrosesan yang biasanya membatasi teknologi pencetakan digital lainnya. Kompatibilitas universal ini berasal dari sifat unik tinta UV-curable yang membentuk ikatan adhesi kuat dengan hampir semua jenis material permukaan, termasuk bahan non-pori yang menolak tinta berbasis air atau pelarut konvensional. Aplikasi pencetakan kaca menunjukkan fleksibilitas ini dengan sempurna, memungkinkan pencetakan langsung grafik, teks, dan gambar foto pada botol, jendela, cermin, serta panel kaca dekoratif dengan kejernihan dan ketahanan luar biasa. Bahan logam seperti aluminium, baja tahan karat, tembaga, dan permukaan yang telah dicat mudah menerima tinta UV, membuka peluang untuk penandaan industri, aplikasi dekoratif, dan rambu khusus yang tetap berkualitas meskipun dalam kondisi lingkungan ekstrem. Material plastik mulai dari akrilik dan polikarbonat yang kaku hingga film fleksibel dan kain sintetis dapat dicetak dengan sangat baik menggunakan printer digital uv murah, memungkinkan produksi kemasan, produk promosi, dan aplikasi khusus yang sebelumnya membutuhkan proses sablon layar atau pad printing yang mahal. Permukaan kayu termasuk kayu alami, papan rekayasa, dan furnitur jadi dapat langsung menerima tinta UV, menciptakan peluang untuk pertukangan kustom, elemen arsitektural, dan aplikasi dekoratif dengan detail fotografi dan akurasi warna. Kemampuan pencetakan tekstil meluas melampaui aplikasi kain tradisional dan mencakup material sintetis, kulit, kanvas, serta tekstil teknis yang digunakan dalam aplikasi industri dan otomotif. Kemampuan mencetak tinta putih sebagai underbase maupun topcoat secara signifikan memperluas kemungkinan kreatif, memungkinkan warna-warna cerah pada bahan gelap serta efek khusus pada material transparan. Printer ini mampu menangani ketebalan bahan mulai dari film tipis berukuran mikron hingga papan kaku setebal beberapa inci, memberikan fleksibilitas untuk beragam kebutuhan produksi tanpa mengorbankan kualitas cetak atau memerlukan modifikasi peralatan. Fleksibilitas terhadap berbagai bahan ini menghilangkan kebutuhan akan beberapa sistem pencetakan khusus, mengurangi biaya peralatan, kebutuhan pelatihan, dan kompleksitas inventaris, sekaligus memperluas kemampuan layanan dan peluang pasar bagi bisnis yang berinvestasi dalam teknologi printer digital uv murah.