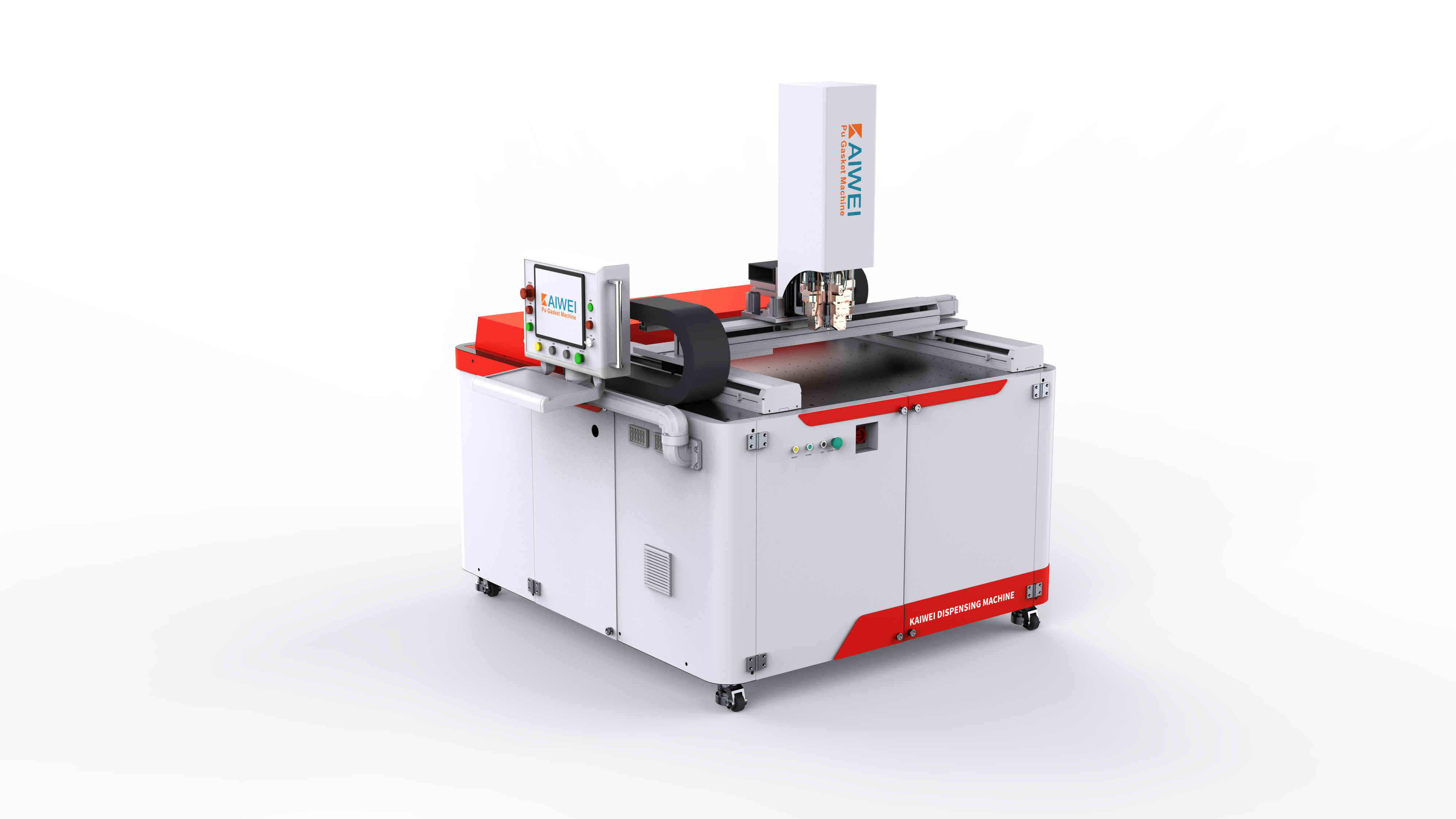

フォーム注入密封装置

フォーム注入シーリング装置は、多様な産業分野において正確かつ効率的なシーリングを実現するために設計された最先端のソリューションです。この高度な機械は、専用のフォーム材料を使用して耐久性があり、耐候性に優れたシールを形成し、構造物を湿気、空気の侵入および環境中の汚染物質から保護します。フォーム注入シーリング装置は、材料の流量、圧力、温度を制御する高度な制御システムを備えており、均一で高品質な施工を保証します。これらの装置には自動ディスペンサー機構が搭載されており、ポリウレタン、シリコーン系、および特定のシーリング要件に合わせた特殊化学化合物など、さまざまなフォーム組成に対応できます。また、混合前にフォーム成分を正確に計量する精密メータリングシステムを備え、最適な化学反応とシール性能を実現しています。最新のフォーム注入シーリング装置にはデジタルモニタリング機能が含まれており、施工パラメータをリアルタイムで追跡することで、オペレーターが品質管理やプロセス最適化のために包括的なデータを取得できるようになっています。この技術には、現場作業向けの携帯型ユニットと大量生産環境向けの据置型システムの両方が含まれます。主要な技術的特徴としては、温度制御付き材料タンク、可変速度ポンプ、プログラマブルな注入サイクル、および異なるシール形状に対応可能な交換可能なノズル構成が挙げられます。本装置は連続ビード塗布、スポットシーリング、空洞充填などの複数の施工方法をサポートしています。上級モデルにはロボットとの統合機能が備わっており、自動化されたシーリング工程により人件費を削減し、一貫性を向上させることができます。安全機能としては、緊急停止システム、圧力解放弁、および作業者が化学物質への暴露から保護されるための遮断プロトコルが含まれます。このフォーム注入シーリング装置は、製品の性能と耐久性にとって信頼性の高いシーリングが不可欠な自動車製造、建設、航空宇宙、船舶、電子機器産業などで広く使用されています。