utstyr for skuminnsperring

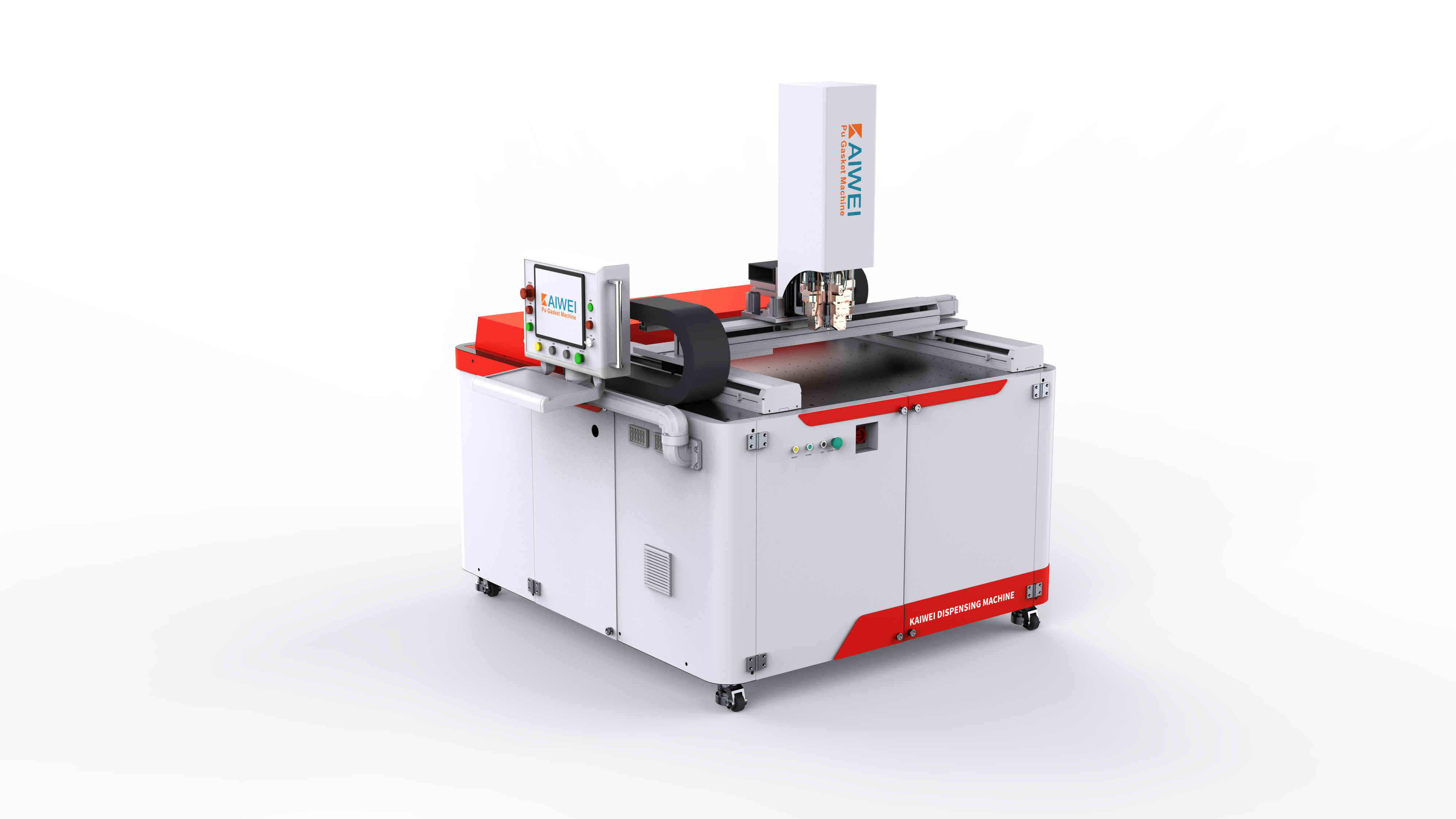

Skråpåfyllingsutstyr for tetting representerer en banebrytende løsning som er utviklet for å gi nøyaktige og effektive tettingsapplikasjoner innen mange industrielle sektorer. Denne avanserte maskinen bruker spesialiserte skummaterialer til å lage varige, værfaste tettinger som beskytter konstruksjoner mot fukt, luftlekkasje og miljøforurensning. Skråpåfyllingsutstyret opererer gjennom sofistikerte kontrollsystemer som regulerer materialestrøm, trykk og temperatur for å sikre konsekvent kvalitet i applikasjonen. Disse maskinene har automatiserte doseringsmekanismer som kan håndtere ulike skumformuleringer, inkludert polyuretan, silikonbaserte og spesielle kjemiske forbindelser tilpasset spesifikke tettingskrav. Utstyret inneholder presisjonsmålesystemer som nøyaktig måler skumkomponentene før blanding, og sikrer optimale kjemiske reaksjoner og tettingsytelse. Moderne skråpåfyllingsutstyr for tetting inkluderer digitale overvåkningsfunksjoner som sporer applikasjonsparametere i sanntid og gir operatører omfattende data for kvalitetskontroll og prosessoptimalisering. Teknologien omfatter både bærbare enheter for feltapplikasjoner og stasjonære systemer for produksjonsmiljøer med høy kapasitet. Nøkkelfunksjoner inkluderer temperaturregulerte materialtanker, pumper med variabel hastighet, programmerbare injeksjons-sykluser og utskiftbare dyskonfigurasjoner som kan tilpasses ulike tettingsgeometrier. Utstyret støtter flere applikasjonsmetoder, inkludert kontinuerlig strippåføring, punkttetting og fylling av hulrom. Avanserte modeller har integreringsmuligheter for roboter, noe som muliggjør automatiserte tettingsprosesser som reduserer arbeidskostnader og forbedrer konsekvens. Sikkerhetsfunksjoner inkluderer nødstopp-systemer, trykkavlastningsventiler og inneslutningsprotokoller som beskytter operatører mot eksponering for kjemikalier. Skråpåfyllingsutstyret for tetting har omfattende bruksområder innen bilproduksjon, bygg, luftfart, maritim og elektronikkindustri der pålitelige tettingsløsninger er avgjørende for produktets ytelse og levetid.