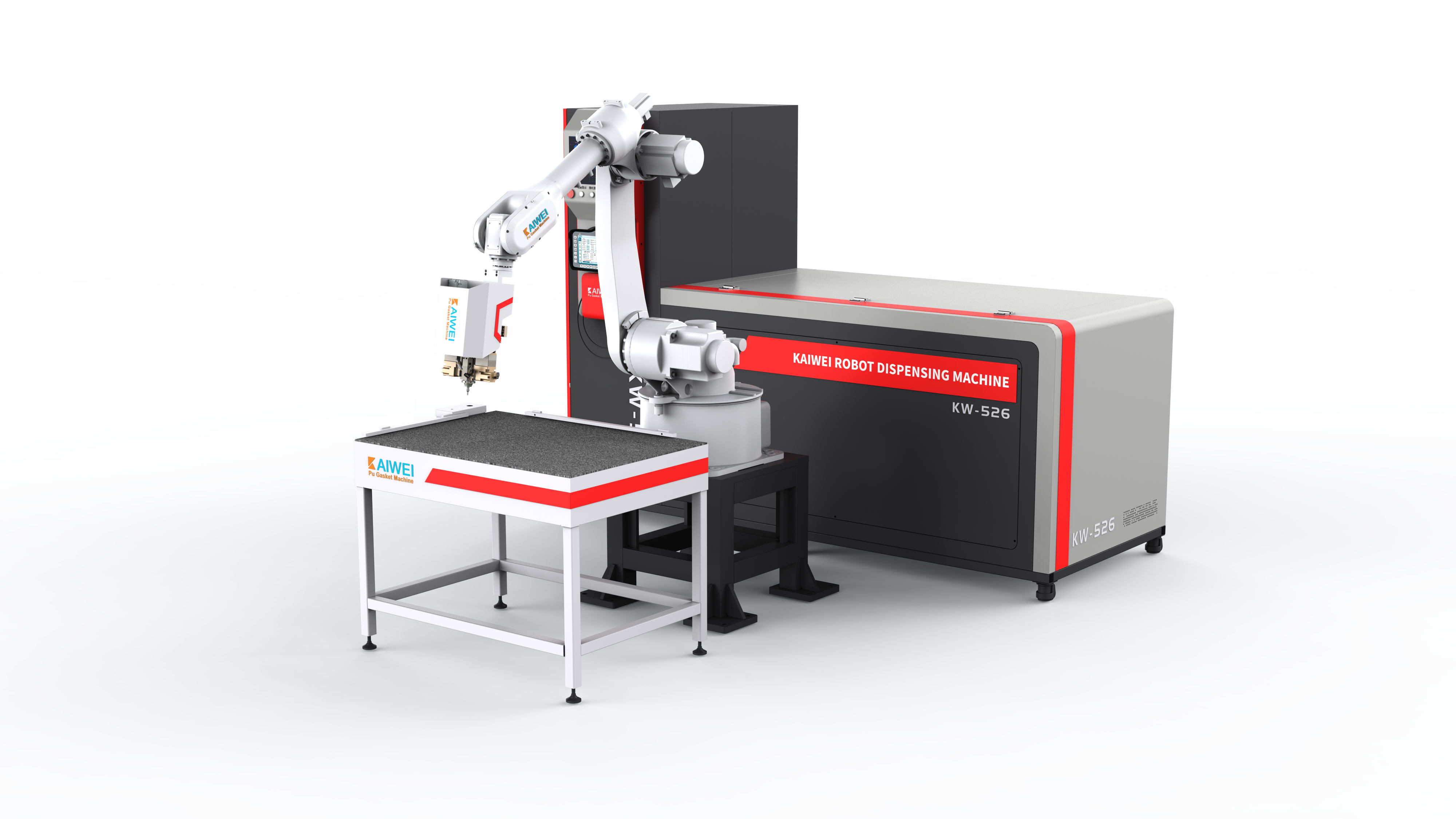

pU発泡機製造業者

ポリウレタン発泡機械メーカーは、複数の産業分野におけるポリウレタンフォーム生産用に設計された高度な設備の製造を専門としています。これらの高度な機械は、フォーム製造工程の基盤として機能し、高品質なポリウレタンフォーム製品を製造するための正確な混合および供給機能を提供します。ポリウレタン発泡機械メーカーが提供する装置の主な機能は、ポリオールとイソシアネート成分を正確に混合し、発泡剤を導入して、均一な密度と特性を持つセル構造フォームを生成することに集中しています。最新の機械には、温度、圧力、混合比率をリアルタイムで監視するコンピュータ制御システムが組み込まれており、最適な化学反応とフォーム膨張を確実に実現します。技術的特徴としては、数ミリ秒以内に成分を完全に混合する高圧衝突混合ヘッドがあり、反応の早期発生を防ぎながらフォームの品質を最大化します。先進的なポリウレタン発泡機械メーカーの設計では、サーボ駆動の計量ポンプを統合することで、成分のドーズ量において卓越した精度を実現しており、加熱された材料ラインによりシステム全体で最適な処理温度が維持されます。これらの機械はモジュラー構造を備えており、小規模な試作から大量生産まで、特定の生産要件に応じたカスタマイズが可能です。応用範囲は、自動車用シートおよび内装部品、建築用断熱パネル、家電製品の断熱材、家具用クッション、包装材、特殊工業用フォーム製品など、多岐にわたります。信頼できるポリウレタン発泡機械メーカーが提供する装置の汎用性により、柔軟性、半硬質、硬質のフォーム配合を、さまざまな密度や機械的特性で製造できます。安全システムには、緊急停止プロトコル、材料漏れ検出、適切な換気連携機能が含まれ、化学物質の取り扱い時の作業者保護を確保します。品質管理機能には、自動パラメータ記録、ロット追跡機能、フォーム特性を最終製品出荷前に検証する統合テストシステムが含まれます。