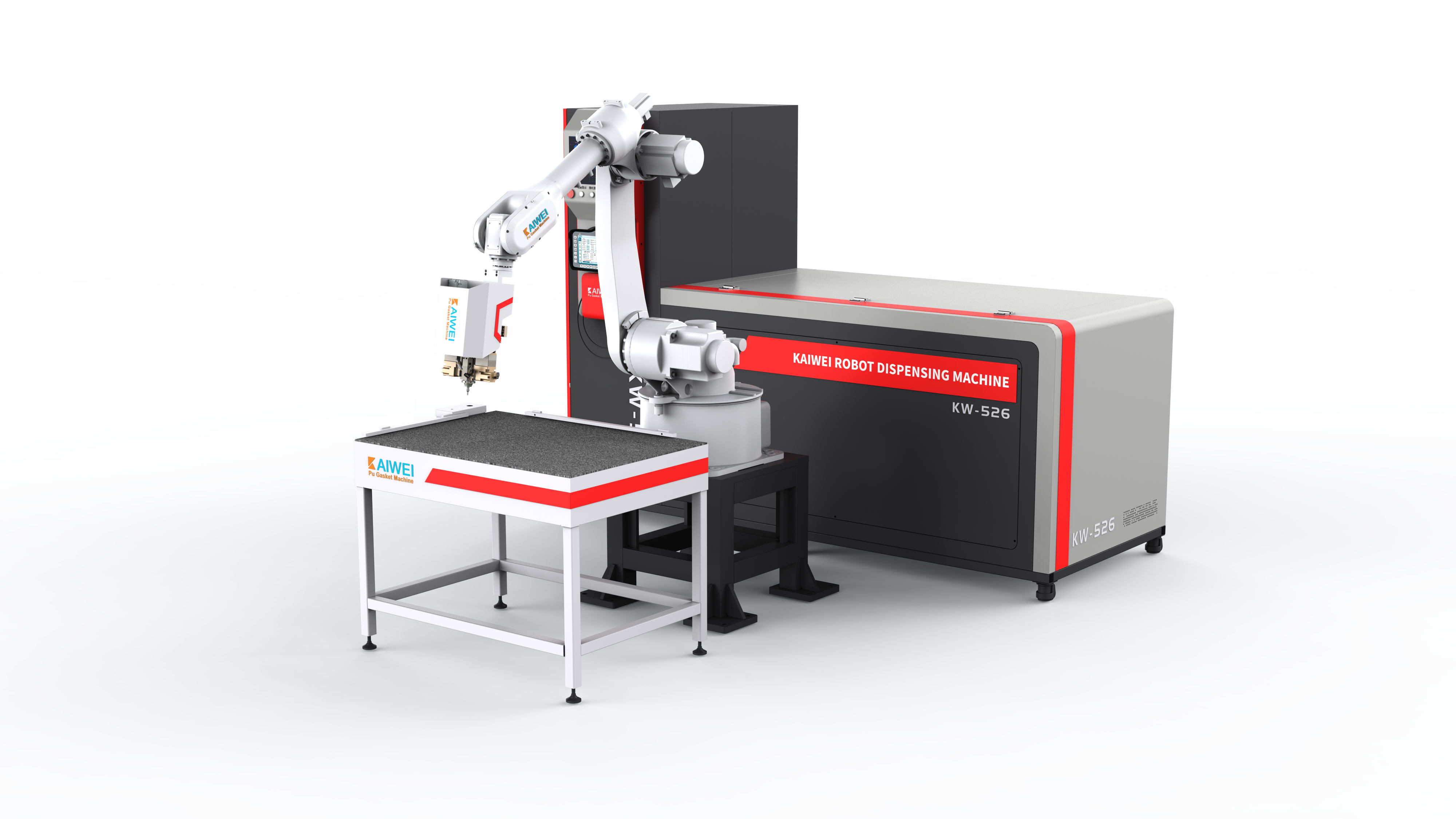

pu foaming machine manufacturer

A pu foaming machine manufacturer specializes in producing advanced equipment designed for polyurethane foam production across multiple industries. These sophisticated machines serve as the cornerstone of foam manufacturing operations, delivering precise mixing and dispensing capabilities for creating high-quality polyurethane foam products. The primary function of equipment from a pu foaming machine manufacturer centers on accurately combining polyol and isocyanate components while introducing blowing agents to create cellular foam structures with consistent density and properties. Modern machines incorporate computerized control systems that monitor temperature, pressure, and mixing ratios in real-time, ensuring optimal chemical reactions and foam expansion. Technological features include high-pressure impingement mixing heads that achieve thorough component blending within milliseconds, preventing premature reactions while maximizing foam quality. Advanced pu foaming machine manufacturer designs integrate servo-driven metering pumps that deliver exceptional accuracy in component dosing, while heated material lines maintain optimal processing temperatures throughout the system. These machines feature modular construction allowing customization for specific production requirements, from small-scale prototyping to high-volume manufacturing operations. Applications span diverse sectors including automotive seating and interior components, construction insulation panels, appliance insulation, furniture cushioning, packaging materials, and specialized industrial foam products. The versatility of equipment from a reputable pu foaming machine manufacturer enables production of flexible, semi-rigid, and rigid foam formulations with varying densities and mechanical properties. Safety systems include emergency shutdown protocols, material leak detection, and proper ventilation integration to ensure operator protection during chemical handling processes. Quality control features encompass automated parameter logging, batch tracking capabilities, and integrated testing systems that verify foam properties before final product release.