producent maszyny do piany PU

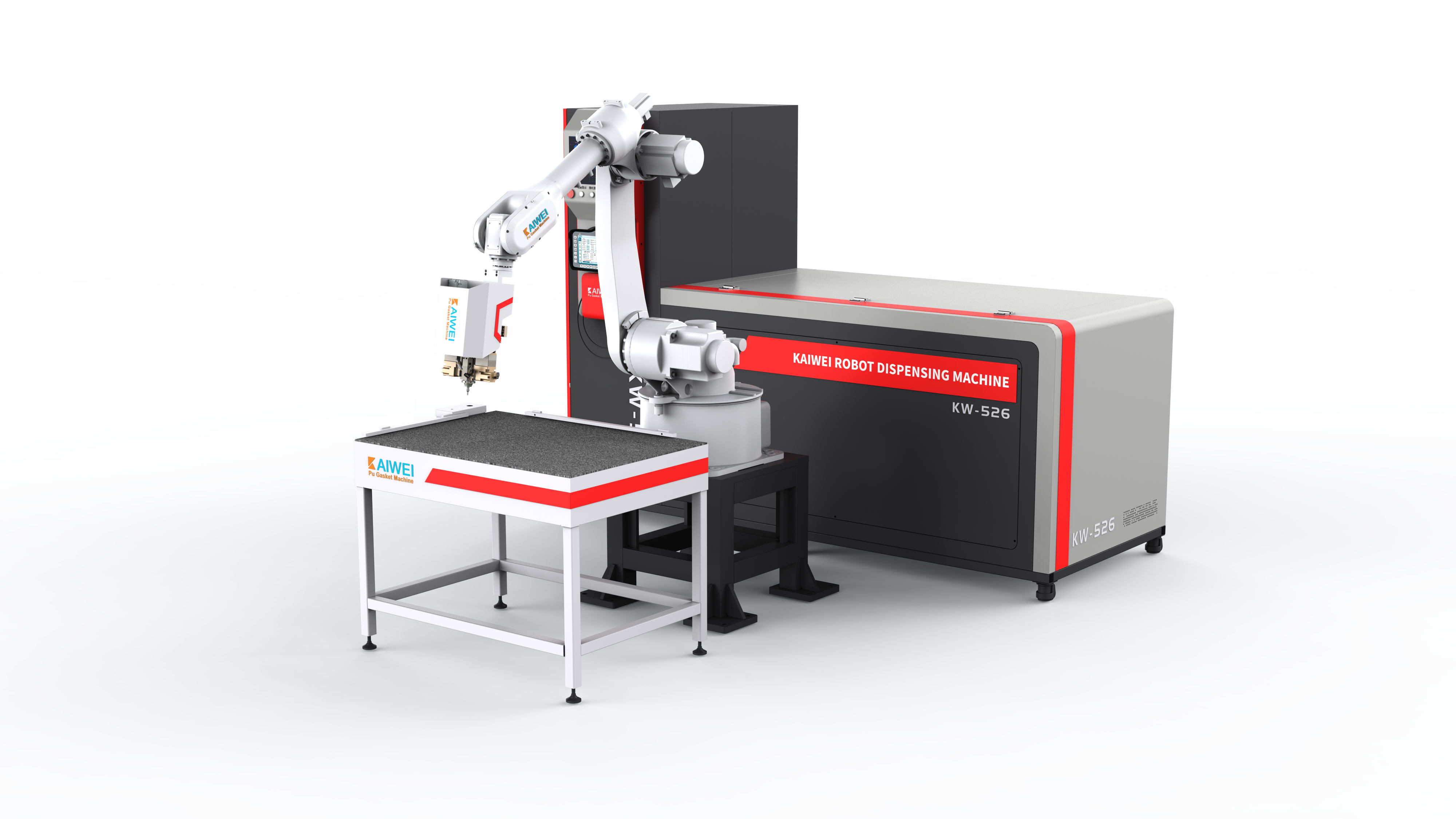

Producent maszyn pianotwórczych specjalizuje się w wytwarzaniu zaawansowanego sprzętu przeznaczonego do produkcji pianek poliuretanowych w różnych branżach. Te złożone urządzenia stanowią podstawę procesów produkcyjnych pianek, zapewniając precyzyjne mieszanie i dawkowanie składników niezbędnym do tworzenia wysokiej jakości wyrobów z pianki poliuretanowej. Główne zadanie sprzętu od producenta maszyn pianotwórczych polega na dokładnym łączeniu składników poliolu i izocyjanianu przy jednoczesnym wprowadzaniu środków spieniających, aby tworzyć komórkowe struktury piankowe o stałej gęstości i właściwościach. Nowoczesne maszyny wyposażone są w systemy sterowania komputerowego monitorujące w czasie rzeczywistym temperaturę, ciśnienie oraz proporcje mieszania, co gwarantuje optymalne reakcje chemiczne i rozwinięcie pianki. Cechy technologiczne obejmują głowice mieszające o wysokim ciśnieniu, które osiągają dokładne wymieszanie składników w ciągu milisekund, zapobiegając przedwczesnym reakcjom i maksymalizując jakość pianki. Zaawansowane konstrukcje maszyn od producenta maszyn pianotwórczych integrują pompy dawkujące napędzane serwomechanizmami, które zapewniają wyjątkową dokładność dawkowania składników, podczas gdy ogrzewane linie materiałowe utrzymują optymalną temperaturę przetwarzania w całym systemie. Te maszyny charakteryzują się budową modułową umożliwiającą dostosowanie do konkretnych wymagań produkcyjnych – od prototypowania w małej skali po operacje produkcyjne o dużej wydajności. Zastosowania obejmują różne sektory, w tym fotelarstwo samochodowe i elementy wnętrza, płyty izolacyjne w budownictwie, izolacje urządzeń gospodarstwa domowego, wykładziny meblowe, materiały opakowaniowe oraz specjalistyczne przemysłowe wyroby piankowe. Uniwersalność sprzętu od renomowanego producenta maszyn pianotwórczych umożliwia wytwarzanie pianek elastycznych, półsztywnych i sztywnych o różnej gęstości oraz właściwościach mechanicznych. Systemy bezpieczeństwa obejmują procedury awaryjnego zatrzymania, wykrywanie przecieków materiałów oraz integrację odpowiedniej wentylacji, zapewniając ochronę operatora podczas procesów manipulowania chemikaliami. Funkcje kontroli jakości obejmują automatyczne rejestrowanie parametrów, śledzenie partii oraz zintegrowane systemy testowe weryfikujące właściwości pianki przed wydaniem produktu końcowego.