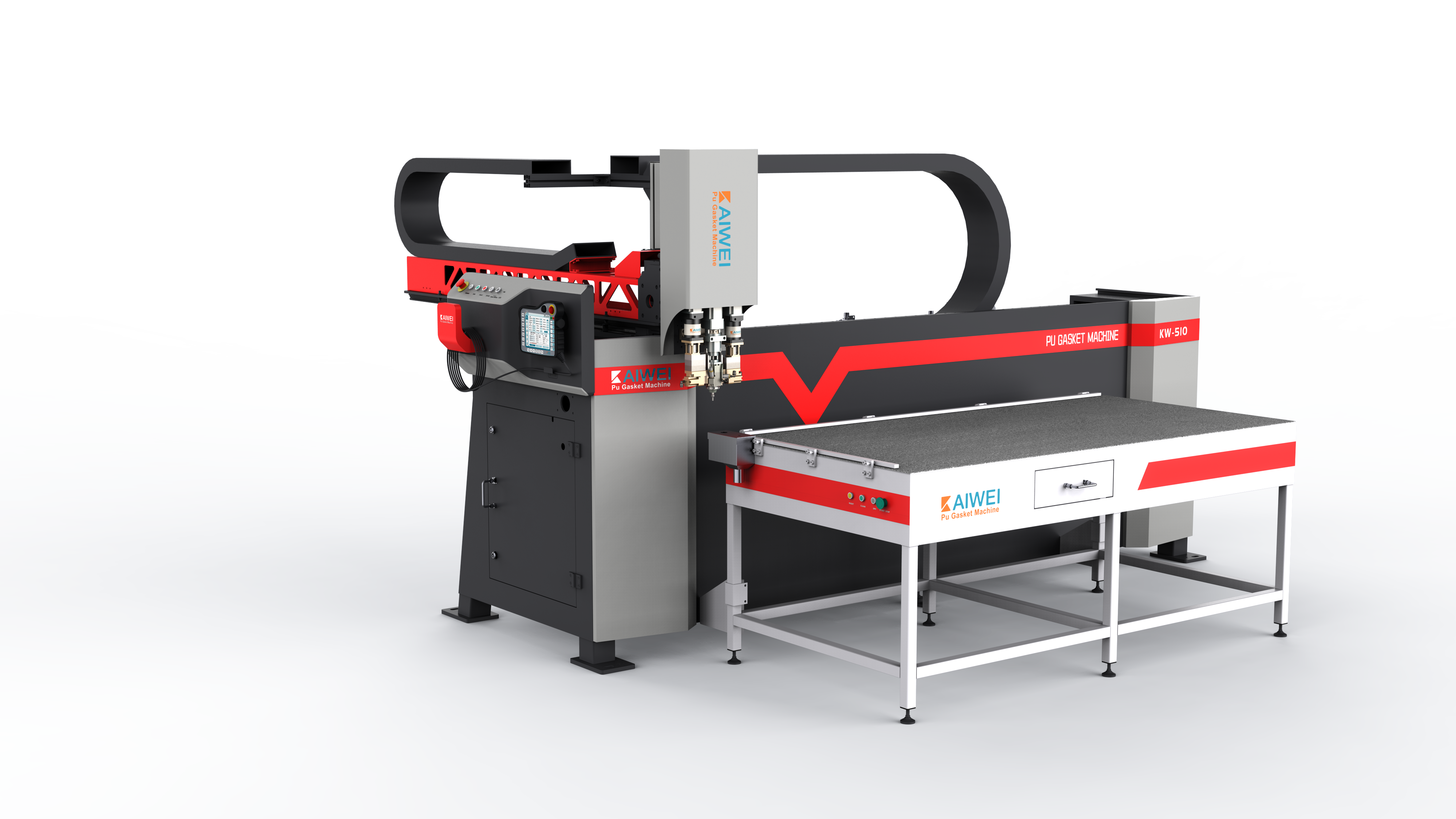

арзанды полиуретан пішін машинасы

Арзан полиуретан түйіршіктер жасау машинасы сапаға әсер етпейтін, бюджет шектеулерін бұзбайтын, бірақ тиімді түйіршіктер өндіру мүмкіндігін қамтамасыз етуге ұмтылатын кәсіпорындар үшін инновациялық шешім болып табылады. Бұл көпфункционалды жабдық әртүрлі салаларда қолданылатын әртүрлі полиуретан түйіршіктер өнімдерін шығарудың негізі болып табылады. Машина полиол мен изоцианат компоненттерін бақыланатын жағдайларда қосып, жоғары сапалы түйіршік материалдарын алу үшін күрделі, бірақ қолдануға ыңғайлы жүйе арқылы жұмыс істейді. Оның негізгі функциясы — тығыздығы, құрылымы және өнім сипаттамалары тұрақты болатындай етіп, химиялық компоненттерді дәл араластыру және тарату. Технологиялық платформа дәл химиялық пропорцияларды қамтамасыз ететін дамытылған өлшеу жүйелерін, оптимальды өңдеу жағдайларын сақтайтын температураны реттеу механизмдерін және біркелкі түйіршіктердің таралуын қамтамасыз ететін автоматтандырылған араластыру камераларын қамтиды. Бұл арзан полиуретан түйіршіктер жасау машиналары түйіршіктерді өндірудегі дәлдікті сақтай отырып, үздіксіз жұмыс істеуге шыдамды, берік құрылымға ие. Жабдыққа әдетте химиялық коррозияға төзімді болаттан жасалған бөлшектер, параметрлерді оңай реттеуге мүмкіндік беретін бағдарламаланатын басқару панельдері және жұмыс істеу кезінде жабдық пен персоналды қорғайтын қауіпсіздік жүйелері кіреді. Қолданылу аясына мебель өндірісі, автомобиль компоненттерін шығару, құрылыста жылу оқшаулау, жинау материалы және арнайы түйіршіктер өнімдері сияқты көптеген салалар кіреді. Өндіріс кәсіпорындары осы машиналарды отыру орындарының төсекшелерін, матрац ядроларын, жылу оқшаулау панельдерін, прокладкалар, сақиналар және қалыпталған түйіршіктер бөлшектерін шығару үшін қолданады. Арзан полиуретан түйіршіктер жасау машинасы қатты да, икемді де түйіршіктерді шығаруға сәйкес келетін әртүрлі түйіршіктер тығыздығы мен құрамын қолдайды. Модульді құрылымы жабдықтың ыңғайлы техникалық қызмет көрсетуін және бөлшектерді ауыстыруды, ал компактілі өлшемі кеңістігі шектеулі объектілерге орнатуға мүмкіндік береді. Машинаның тиімділігі материалдарды тез өңдеуге және тұрақты шығу сапасын сақтауға қабілетті болуынан туындайды, сондықтан кіші және орта көлемді өндіріс операциялары үшін тиімді түйіршіктер өндіру шешімін таңдауға идеалды нұсқа болып табылады.