cheap polyurethane foaming machine

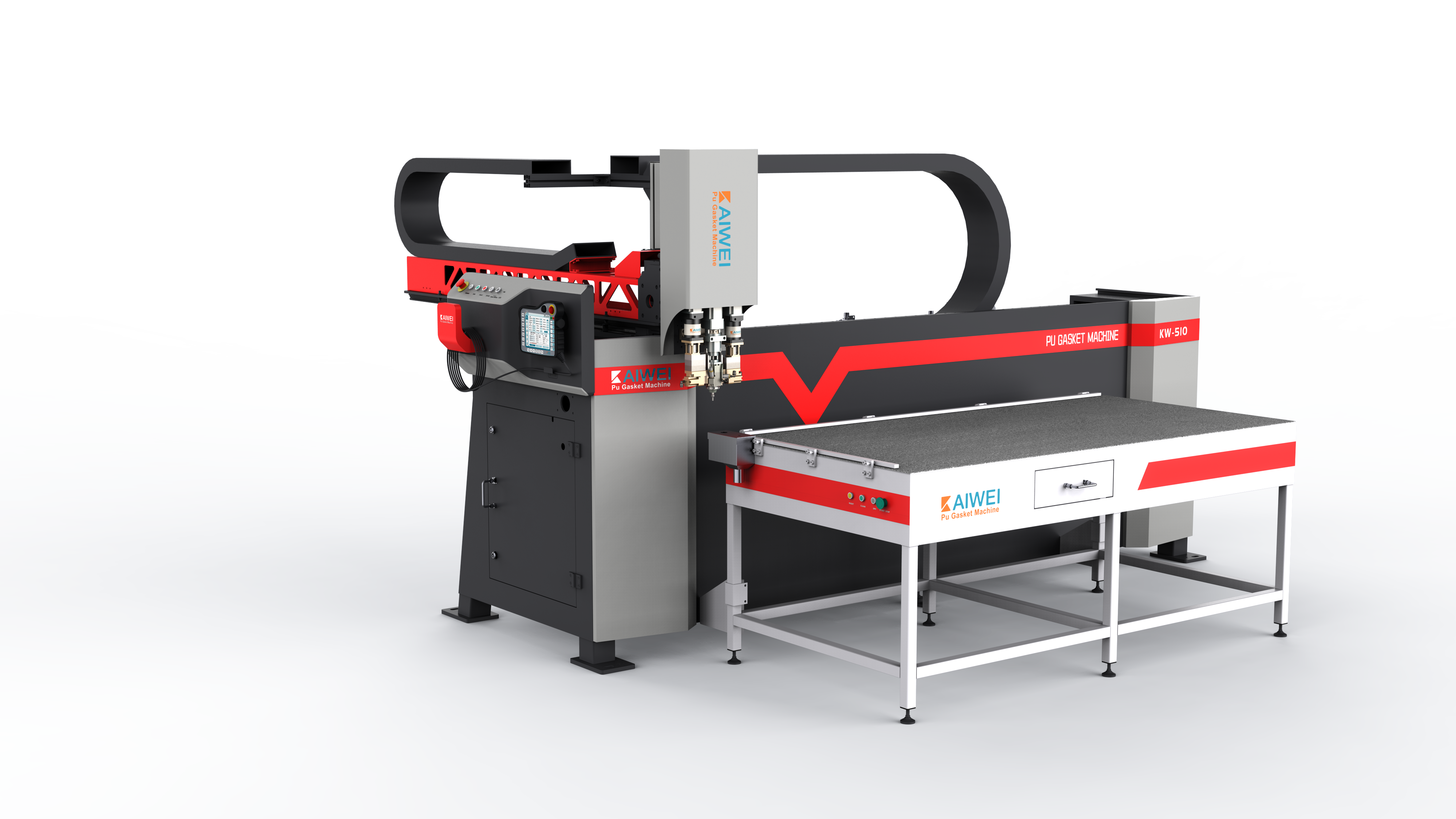

The cheap polyurethane foaming machine represents an innovative solution for businesses seeking efficient foam production capabilities without compromising on quality or breaking their budget constraints. This versatile equipment serves as the backbone for manufacturing various polyurethane foam products used across multiple industries. The machine operates through a sophisticated yet user-friendly system that combines polyol and isocyanate components under controlled conditions to create high-quality foam materials. Its primary function involves the precise mixing and dispensing of chemical components to produce foam with consistent density, structure, and performance characteristics. The technological framework incorporates advanced metering systems that ensure accurate chemical ratios, temperature control mechanisms that maintain optimal processing conditions, and automated mixing chambers that guarantee uniform foam distribution. These cheap polyurethane foaming machines feature robust construction designed to withstand continuous operation while maintaining precision in foam production. The equipment typically includes stainless steel components that resist chemical corrosion, programmable control panels that allow operators to adjust parameters easily, and safety systems that protect both equipment and personnel during operation. Applications span numerous sectors including furniture manufacturing, automotive component production, construction insulation, packaging materials, and specialty foam products. Manufacturing facilities utilize these machines to produce seat cushions, mattress cores, insulation panels, gaskets, seals, and custom-molded foam components. The cheap polyurethane foaming machine accommodates various foam densities and formulations, making it suitable for producing both rigid and flexible foam types. Its modular design allows for easy maintenance and component replacement, while the compact footprint enables installation in facilities with limited space requirements. The machine's efficiency stems from its ability to process materials quickly while maintaining consistent output quality, making it an ideal choice for small to medium-scale production operations seeking cost-effective foam manufacturing solutions.