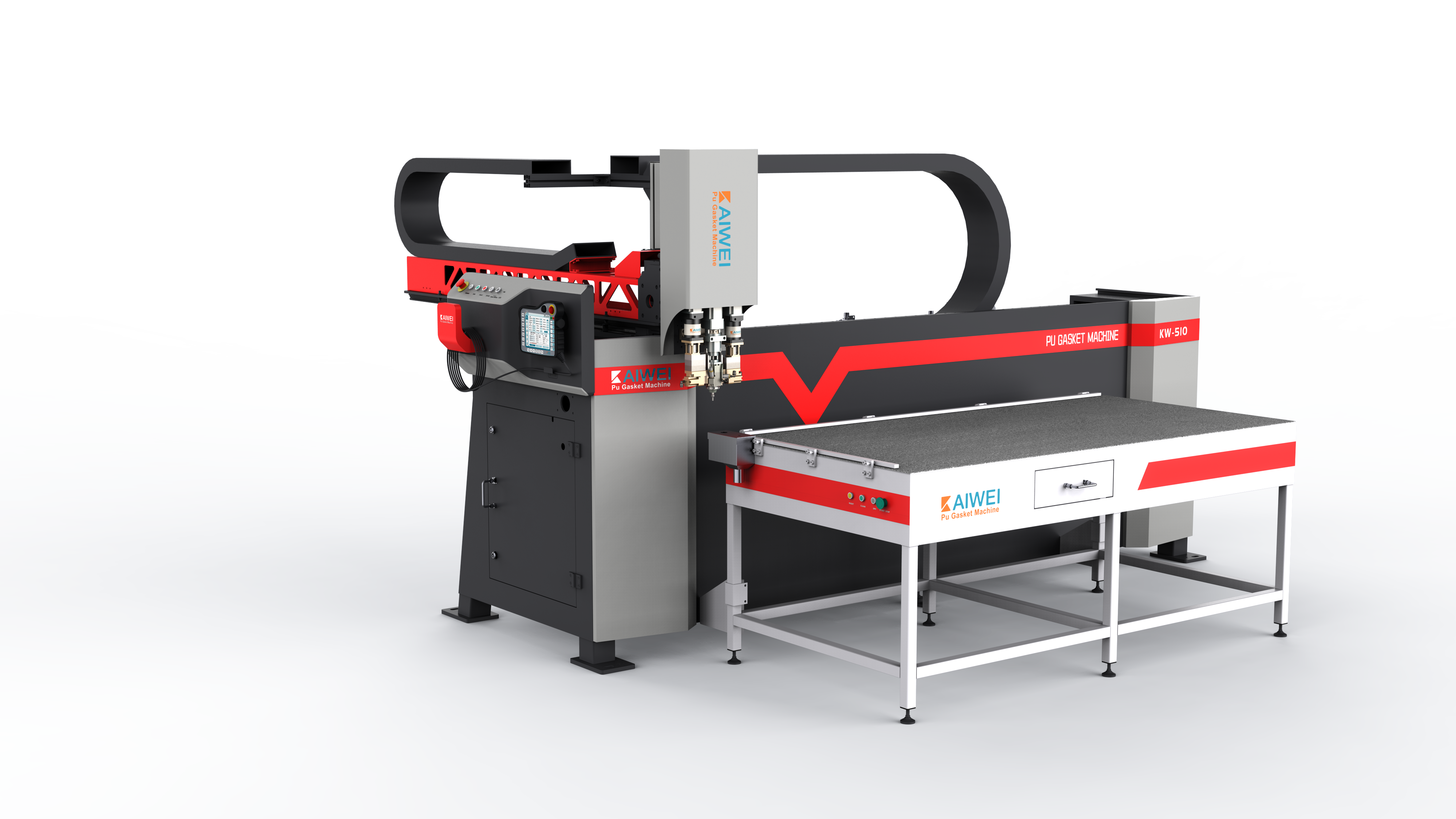

lacný polyuretanový pénový stroj

Nedrahý stroj na pena polymérov je inovatívnym riešením pre podniky, ktoré hľadajú efektívne možnosti výroby peny bez kompromitovania kvality ani prekročenia rozpočtových obmedzení. Toto univerzálne zariadenie tvorí základ výroby rôznych výrobkov z penového polyuretánového materiálu používaných vo viacerých odvetviach priemyslu. Stroj pracuje prostredníctvom sofistikovaného, no zároveň užívateľsky prívetivejšieho systému, ktorý kombinuje zložky polyolu a izokyanátu za kontrolovaných podmienok a vytvára tak kvalitné penové materiály. Jeho hlavnou funkciou je presné miešanie a dávkovanie chemických zložiek za účelom výroby peny s konštantnou hustotou, štruktúrou a prevádzkovými vlastnosťami. Technologický rámec zahŕňa pokročilé dávkovacie systémy, ktoré zabezpečujú presné chemické pomery, mechanizmy riadenia teploty, ktoré udržiavajú optimálne podmienky spracovania, a automatické miešacie komory, ktoré zaručujú rovnomerné rozdelenie peny. Tieto lacné stroje na pena polymérov majú robustnú konštrukciu navrhnutú tak, aby vydržala nepretržitý prevádzok a zároveň zachovala presnosť pri výrobe peny. Zariadenie zvyčajne obsahuje komponenty z nehrdzavejúcej ocele odolnej voči chemickej korózii, programovateľné ovládacie panely umožňujúce jednoduché nastavenie parametrov pre operátorov a bezpečnostné systémy chrániace počas prevádzky ako zariadenie, tak aj personál. Aplikácie sa vyskytujú v mnohých odvetviach vrátane výroby nábytku, výroby automobilových súčiastok, tepelnej izolácie v stavebníctve, balenie materiálov a špeciálnych penových výrobkov. Výrobné zariadenia využívajú tieto stroje na výrobu sedacích vankúšov, jadier matrácov, izolačných dosiek, tesnení, utlakov a špeciálne formovaných penových komponentov. Lacný stroj na pena polymérov umožňuje výrobu rôznych hustôt a zložení peny, čo ho robí vhodným pre výrobu tuhých aj mäkkých typov peny. Jeho modulárny dizajn umožňuje jednoduchú údržbu a výmenu komponentov, zatiaľ čo kompaktné rozmery umožňujú inštaláciu do priestorov s obmedzenými plochami. Efektivita stroja vyplýva z jeho schopnosti rýchlo spracovávať materiály a zároveň udržiavať konštantnú kvalitu výstupu, čo ho robí ideálnou voľbou pre malé až stredné výrobné prevádzky, ktoré hľadajú nákladovo efektívne riešenia výroby peny.