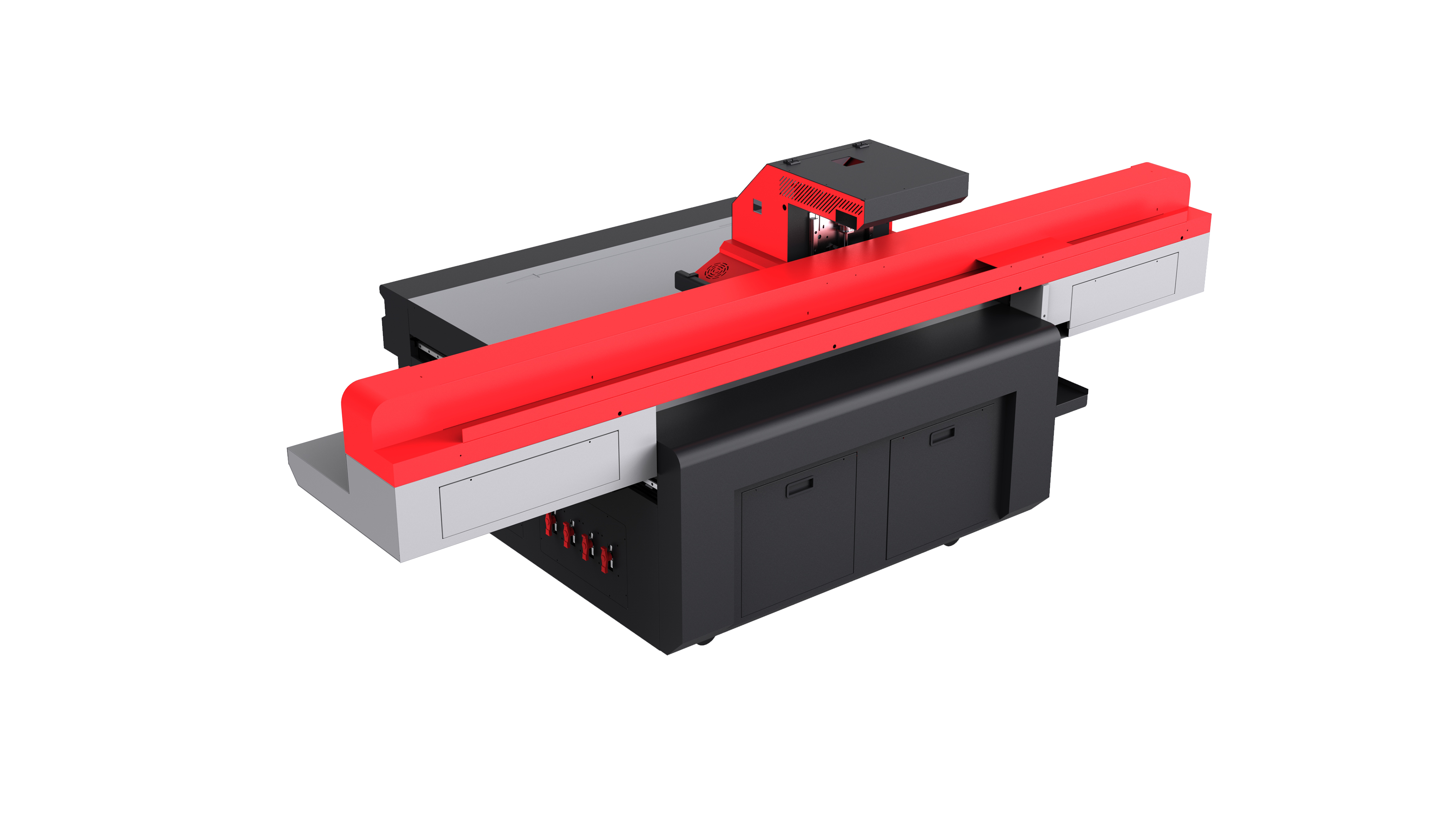

Uovertruffen underlagets mangfoldighet og vedhefting

Den effektive UV-digitalskriverens eksepsjonelle kompatibilitet med ulike underlag representerer en banebrytende egenskap som utvider forretningsmuligheter langt utover begrensningene til konvensjonelle trykkteknologier. Mens tradisjonelle skrivere vanligvis begrenser brukerne til papir, papp og lignende porøse materialer, binder den effektive UV-digitalskriveren UV-blekkene til nesten alle typer underlag, inkludert metaller, glass, keramikk, stive plastmaterialer, tre, stein og sammensatte materialer, uten behov for primer, forbehandling eller overflateendringer som øker kostnadene og kompliserer produksjonsprosessene. Denne allsidigheten skyldes de unike egenskapene til UV-blekk som herdes til en fleksibel polymertil som kan binde seg til glatte, ikke-porøse overflater, samtidig som det beholder fleksibilitet for å tåle varmeutvidelse og -kontraksjon uten å sprekke eller bladre av. Bedrifter kan diversifisere sine tjenester til å omfatte høyverdifulle applikasjoner som arkitektoniske glasspaneler, metalskilt, priser og anerkjennelser, industrielle navneskilter og reklameartikler som tillater premium-prissetting i forhold til tradisjonelle papirbaserte materialer. Den effektive UV-digitalskriveren muliggjør direkte dekorering av tredimensjonale objekter og uregelmessig formede gjenstander, noe som eliminerer behovet for mellomliggende overføringsprosesser eller spesialiserte monteringsprosedyrer som øker produksjonstiden og materialkostnadene. Ytterligere holdbarhet blir eksepsjonell ettersom UV-hardedde blekk motstår misfarging fra langvarig sollys, bevarer fargestabilitet gjennom ekstreme temperatursvingninger og gir vannfast ytelse som fjerner bekymring for værskader eller fuktighetssprekk. Skriverens evne til å binde seg til transparente underlag som akryll eller glass skaper muligheter for lysbakete visninger, vindusgrafikk og arkitektoniske applikasjoner der lysgjennomgang og fargestyrke må eksistere side om side. De kjemiske motstandsdyktige egenskapene til UV-hardedde blekk gjør den effektive UV-digitalskriveren ideell for industrielle applikasjoner der utskriftsmaterialer må tåle eksponering for rengjøringsmidler, oljer eller andre harde kjemikalier uten nedbrytning. Krav til overflateforberedelse forblir minimale, og krever vanligvis kun grunnleggende rengjøring for å fjerne støv eller oljer, noe som reduserer arbeidskostnader og produksjonstid betydelig i forhold til tradisjonelle trykkmetoder som kan kreve sløying, primer eller kjemisk etsing. Den konsekvente blekkheftingen på tvers av ulike typer underlag eliminerer behovet for omfattende testing og justering når man bytter mellom materialer, noe som forenkler produksjonsarbeidsflyten og reduserer oppstartstid som tradisjonelt har skapt ineffektiviteter ved håndtering av mangfoldige kundekrav.