Nieprowdzana różnorodność podłoży i przyczepność

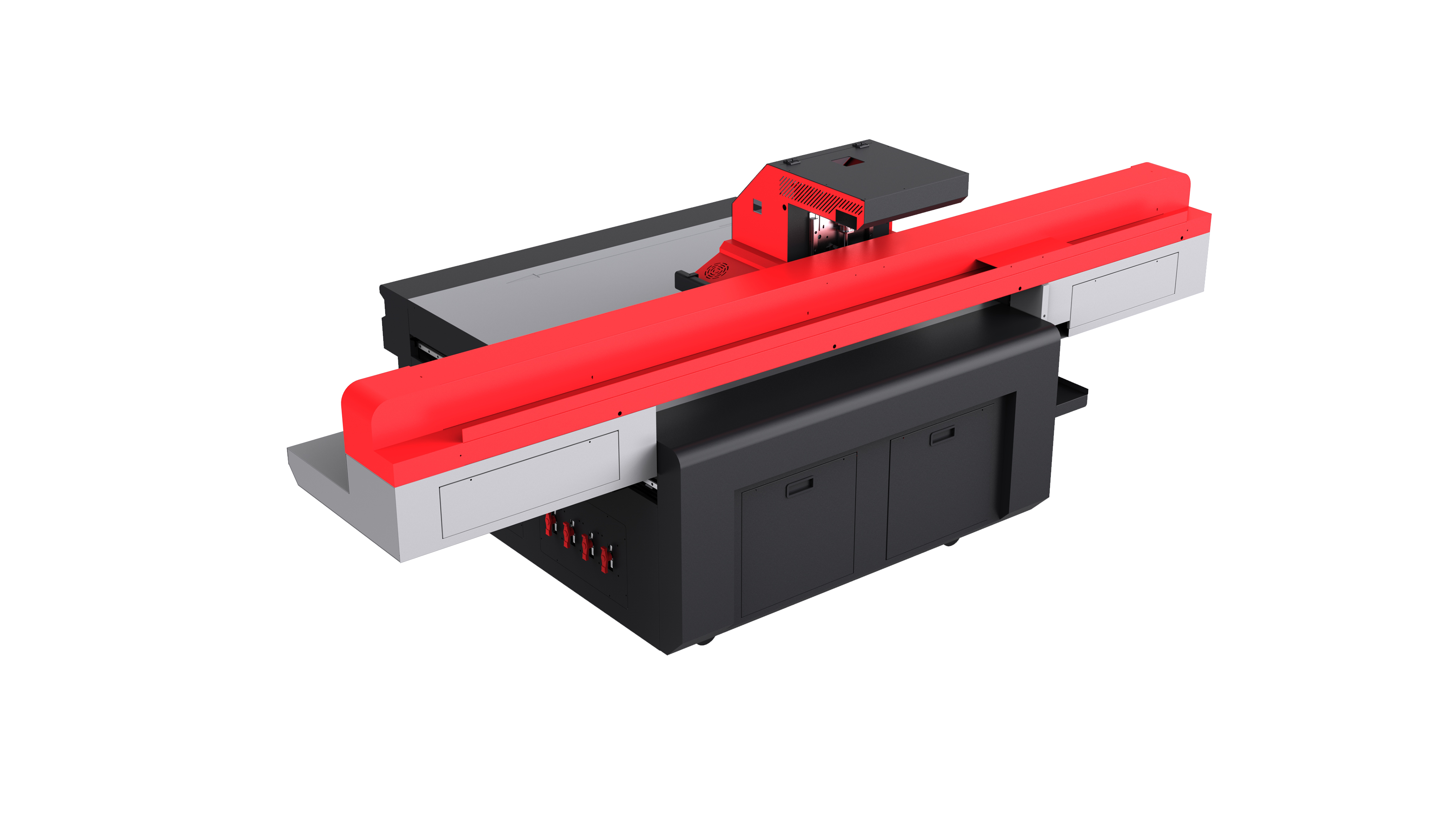

Wydajny drukarz cyfrowy UV o wyjątkowej kompatybilności z podłożami stanowi przełomową możliwość, która znacznie poszerza horyzonty działalności gospodarczej poza ograniczenia tradycyjnych technologii drukowania. Podczas gdy konwencjonalne drukarki zazwyczaj ograniczają użytkowników do papieru, tektury i podobnych materiałów porowatych, wydajny drukarz cyfrowy UV skutecznie wiąże farby UV z praktycznie każdym rodzajem podłoża, w tym metalami, szkłem, ceramiką, sztywnymi plastikami, drewnem, kamieniem oraz materiałami kompozytowymi, bez konieczności stosowania gruntów, wstępnych obróbek ani modyfikacji powierzchni, które dodatkowo zwiększają koszty i komplikują procesy produkcyjne. Ta wszechstronność wynika z unikalnych właściwości farb UV, które utwardzają się w elastyczną folię polimerową zdolną przylegać do gładkich, nieporowatych powierzchni, zachowując jednocześnie elastyczność umożliwiającą kompensację rozszerzalności termicznej bez pękania czy odwarstwiania. Firmy mogą poszerzyć ofertę usług o aplikacje o wysokiej wartości, takie jak panele szklane architektoniczne, tablice metalowe, nagrody i dyplomy, tabliczki identyfikacyjne przemysłowe oraz produkty promocyjne, cieszące się wyższymi cenami w porównaniu do tradycyjnych materiałów papierowych. Wydajny drukarz cyfrowy UV umożliwia bezpośrednią dekorację trójwymiarowych obiektów i przedmiotów o nieregularnych kształtach, eliminując potrzebę pośrednich procesów przenoszenia lub specjalistycznych procedur montażowych, które wydłużają czas produkcji i zwiększają koszty materiałowe. Trwałość użytkowania w warunkach zewnętrznych jest nadzwyczajna, ponieważ utwardzone farby UV odporniejsze są na wypalanie przez długotrwałe działanie światła słonecznego, zachowują stabilność barw przy ekstremalnych wahaniach temperatury oraz zapewniają wodoszczelność, dzięki czemu nie ma obawy przed uszkodzeniami pogodowymi czy przenikaniem wilgoci. Możliwość drukowania na przezroczystych podłożach, takich jak akryl lub szkło, otwiera nowe możliwości dla aplikacji oświetlanych z tyłu, grafik okiennych oraz rozwiązań architektonicznych, gdzie współistnieć muszą przepuszczalność światła i intensywność kolorów. Właściwości odporności chemicznej utwardzonych farb UV czynią wydajny drukarz cyfrowy UV idealnym rozwiązaniem dla zastosowań przemysłowych, gdzie wydruki muszą wytrzymać kontakt z detergentami, olejami lub innymi agresywnymi substancjami chemicznymi bez degradacji. Wymagania dotyczące przygotowania powierzchni pozostają minimalne – zazwyczaj wystarczy podstawowe oczyszczenie z pyłu lub tłuszczu – co znacząco redukuje koszty pracy i czas produkcji w porównaniu do tradycyjnych metod druku, wymagających często szlifowania, gruntowania lub trawienia chemicznego. Spójne przyleganie farby do różnych typów podłoży eliminuje potrzebę wnikliwych testów i dostrojeń przy zmianie materiałów, upraszczając procesy produkcyjne i skracając czas przygotowania, który wcześniej był przyczyną nieskuteczności przy realizacji różnorodnych zamówień klientów.