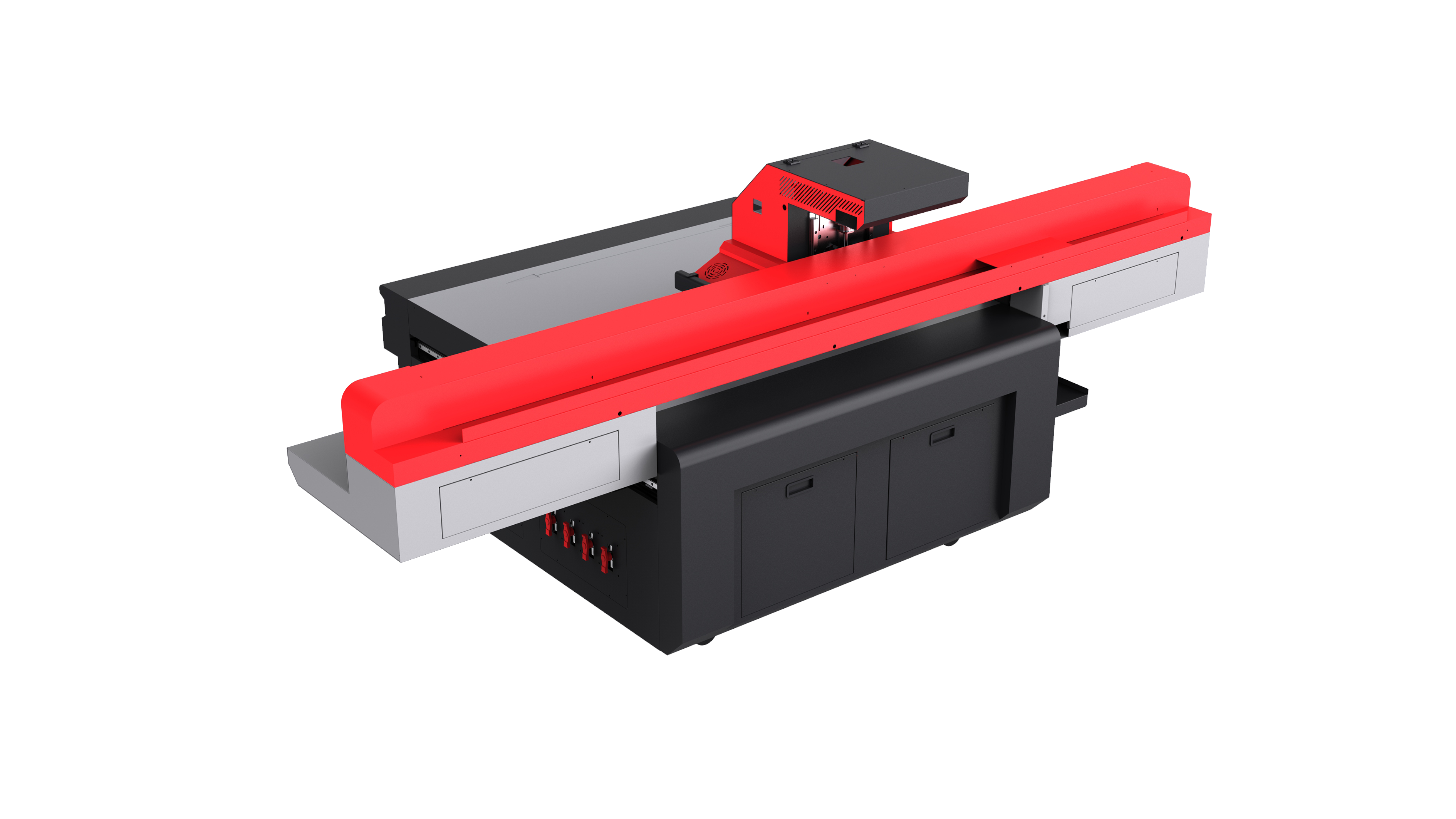

เครื่องพิมพ์ uv แบบแผ่นขายส่ง

เครื่องพิมพ์ยูวีเฟลตแบดแบบขายส่ง ถือเป็นเทคโนโลยีการพิมพ์ขั้นปฏิวัติที่เปลี่ยนโฉมวงการการพิมพ์เชิงพาณิชย์ทั่วโลก เครื่องพิมพ์รุ่นทันสมัยเหล่านี้ใช้แสงอัลตราไวโอเลต (UV) เพื่อทำให้หมึกที่ออกแบบมาเฉพาะแข็งตัวทันที จึงสามารถสร้างงานพิมพ์ที่มีสีสันสดใสและคงทนบนพื้นผิวของวัสดุเกือบทุกชนิด ตลาดเครื่องพิมพ์ยูวีเฟลตแบดแบบขายส่งตอบสนองความต้องการของธุรกิจที่มองหาโซลูชันการพิมพ์คุณภาพสูงในราคาที่แข่งขันได้เมื่อสั่งซื้อจำนวนมาก ทำให้บริษัททุกขนาดสามารถเข้าถึงเทคโนโลยีการพิมพ์ขั้นสูงได้ง่ายยิ่งขึ้น หัวใจหลักของการทำงานของเครื่องพิมพ์เหล่านี้อยู่ที่ความสามารถในการพิมพ์โดยตรงลงบนวัสดุแข็ง โดยไม่จำเป็นต้องมีขั้นตอนการเตรียมพื้นผิวล่วงหน้าหรือขั้นตอนการแปรรูปหลังพิมพ์ เครื่องพิมพ์ยูวีเฟลตแบดใช้หัวพิมพ์แบบพีโซอิเล็กทริกในการวางหมึกที่สามารถแข็งตัวด้วยแสง UV อย่างแม่นยำลงบนวัสดุ จากนั้นจะมีการฉายแสงด้วยหลอดไฟ LED แบบ UV ทันทีเพื่อทำให้หมึกแข็งตัวทันที กระบวนการนี้รับประกันคุณภาพงานพิมพ์ระดับสูง มีรายละเอียดคมชัด สีสันสดใส และยึดเกาะได้อย่างยอดเยี่ยม คุณสมบัติทางเทคโนโลยีของเครื่องพิมพ์ยูวีเฟลตแบดแบบขายส่ง ได้แก่ เทคโนโลยีหยดหมึกแบบแปรผันเพื่อให้ได้เฉดสีที่เรียบเนียน ความสามารถในการใช้หมึกสีขาวเพื่อเพิ่มความทึบบนพื้นผิวสีเข้ม และการพิมพ์หลายชั้นเพื่อสร้างเอฟเฟกต์พื้นผิว รุ่นขั้นสูงจะมีระบบตรวจจับสื่อแบบอัตโนมัติ โต๊ะสูญญากาศที่มีความแม่นยำเพื่อความมั่นคงของวัสดุ และซอฟต์แวร์จัดการสีขั้นสูง เครื่องพิมพ์เหล่านี้รองรับรูปแบบไฟล์ต่างๆ เช่น PDF, TIFF และ EPS ทำให้สามารถผสานรวมกับเวิร์กโฟลว์การออกแบบที่มีอยู่ได้อย่างราบรื่น การประยุกต์ใช้งานเครื่องพิมพ์ยูวีเฟลตแบดแบบขายส่งครอบคลุมอุตสาหกรรมหลายประเภท ได้แก่ การผลิตป้ายโฆษณา การผลิตสินค้าโปรโมชัน การตกแต่งสถาปัตยกรรม การทำต้นแบบบรรจุภัณฑ์ และการสร้างของขวัญแบบกำหนดเอง เครื่องจักรอเนกประสงค์เหล่านี้สามารถพิมพ์บนวัสดุหลากหลายชนิด ตั้งแต่แผ่นอะคริลิกและโลหะ ไปจนถึงไม้ กระจก กระเบื้องเซรามิก และวัสดุยืดหยุ่น ตลาดขายส่งช่วยให้ธุรกิจสามารถเข้าถึงเทคโนโลยีนี้ได้อย่างคุ้มค่า ทำให้สามารถขยายขอบเขตการให้บริการและเพิ่มอัตรากำไรจากการผลิตภายในองค์กร