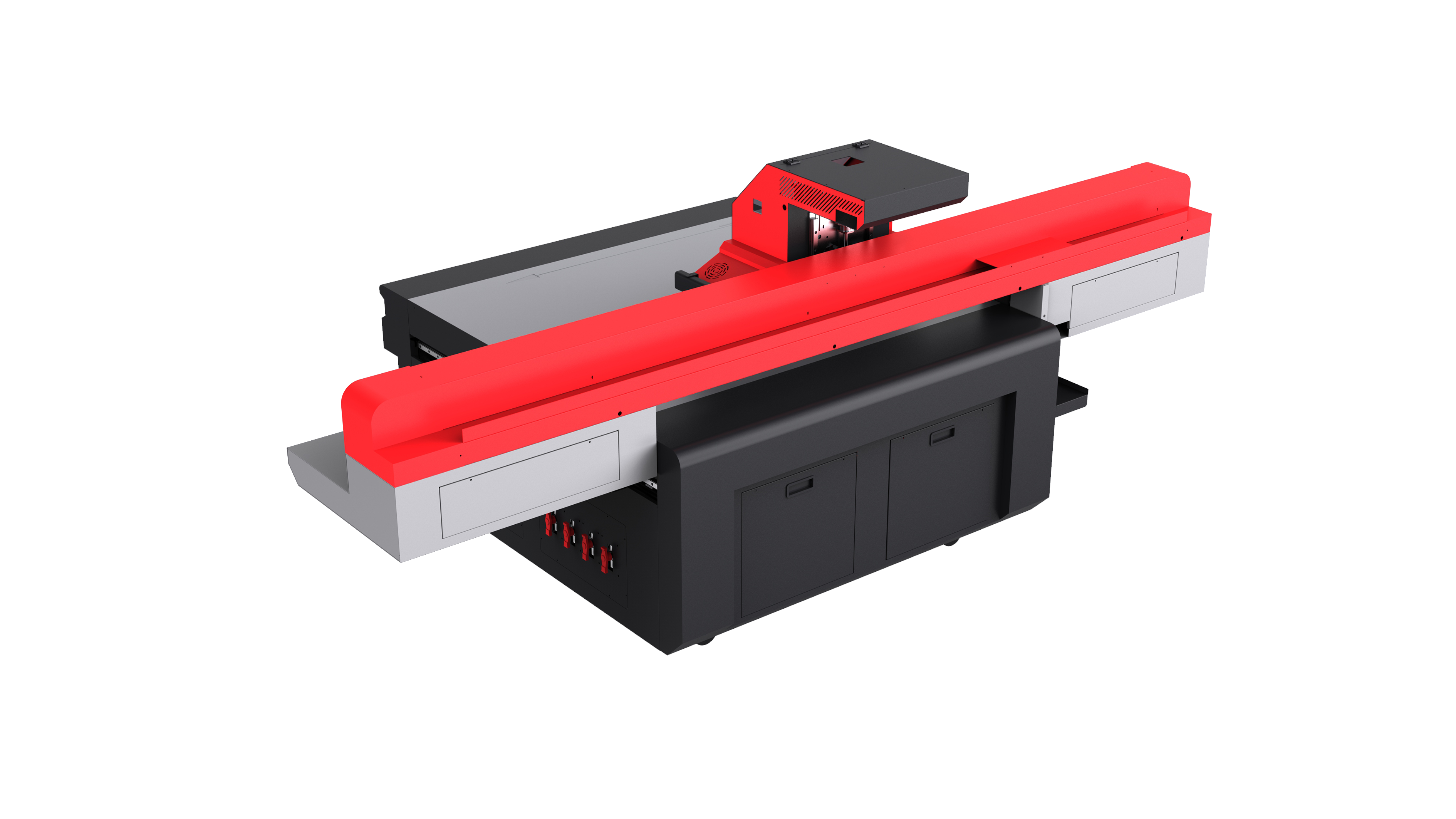

uV tsifrovaya platnaya pechatnaya mashina

Uv raqamli tekis yotiq printeri turli sohalardagi korxonalar uchun noyob moslashuvchanlik va aniqni taklif qiluvchi raqamli bosmaxonachilik texnologiyasidagi inqilobiy yutuqdir. Ushbu murakkab bosish tizimi maxsus tayyorlangan muloyimlarni darhol qattiq shtamplovchi ultrabinafsha nurlaridan foydalanadi va deyarli barcha tekis sirtga yorqin, chidamli bosish imkonini beradi. Uv raqamli tekis yotiq printerining asosiy funksiyalari o'tkazish varag'i yoki qo'shimcha qayta ishlash bosqichlariga ehtiyoj bo'lmaydigan materiallarga bevosita bosishni o'z ichiga oladi. Texnologiya muloyimlarni substrat bilan aloqada bo'lganda darhol qattiqlovchi UV LED quritish tizimlari bilan birlashtirilgan ilg'or inkjet bosish mexanizmlarini o'z ichiga oladi. Asosiy texnologik xususiyatlarga ajoyib tasvir sifatini ta'minlovchi o'zgaruvchan tomchili texnologiya, aniq rang mosligi uchun aniqlik tizimi hamda turli qalinlikdagi materiallarni qo'llab-quvvatlovchi avtomatlashtirilgan balandlikni sozlash imkoniyati kiradi. Zamonaviy uv raqamli tekis yotiq printer modellarida bir nechta fayl formatlari va rang boshqaruv tizimlarini qo'llab-quvvatlaydigan murakkab dasturiy ta'minot integratsiyasi mavjud bo'lib, natijada sifat barqaror saqlanadi. Bosish stolining o'lchamlari odatda bir necha metr kenglik va uzunlikdagi varaqchalarni qayta ishlash qobiliyatiga ega bo'lgan kichik stol modellaridan tortib katta sanoat birligigacha bo'ladi. Uv raqamli tekis yotiq printer texnologiyasining qo'llanilishi belgilarni ishlab chiqarish, paketlash dizayni, reklama materiallarini ishlab chiqarish, arxitektonik bezaklar va shaxsiylashtirilgan mahsulotlarni yaratish kabi ko'plab sohalarni qamrab oladi. Bu tizimlar akrilik, yog'och, metall, shisha, keramika poyafzallari va koplamalar kabi qattiq materiallarga yuqori sifatli grafikalar yaratishda a'lo natija beradi. Oq muloyim va maxsus ranglarni bosish imkoniyati dizaynerlar va ishlab chiqaruvchilar uchun qo'shimcha ijodiy imkoniyatlarni ochadi. Sanoatdagi qo'llanilishi prototiplarni yaratish, bezak paneli, savdo-dukondagi displeylar va maxsus ichki dizayn elementlarini yaratishni o'z ichiga oladi. UV bosishning atrof-muhitga bo'lgan afzalliklari an'anaviy erituvchi asosdagi bosish usullariga nisbatan uchuvchan organik birikmalar chiqindilarini kamaytirishdan iborat bo'lib, bu sifat yoki ishlab chiqarish hajmini qurbon qilmagan holda barqaror bosish echimlarini izlovchi ekologik jihatdan mas'ul bizneslar uchun uv raqamli tekis yotiq printerini ekologik toza tanlov qiladi.