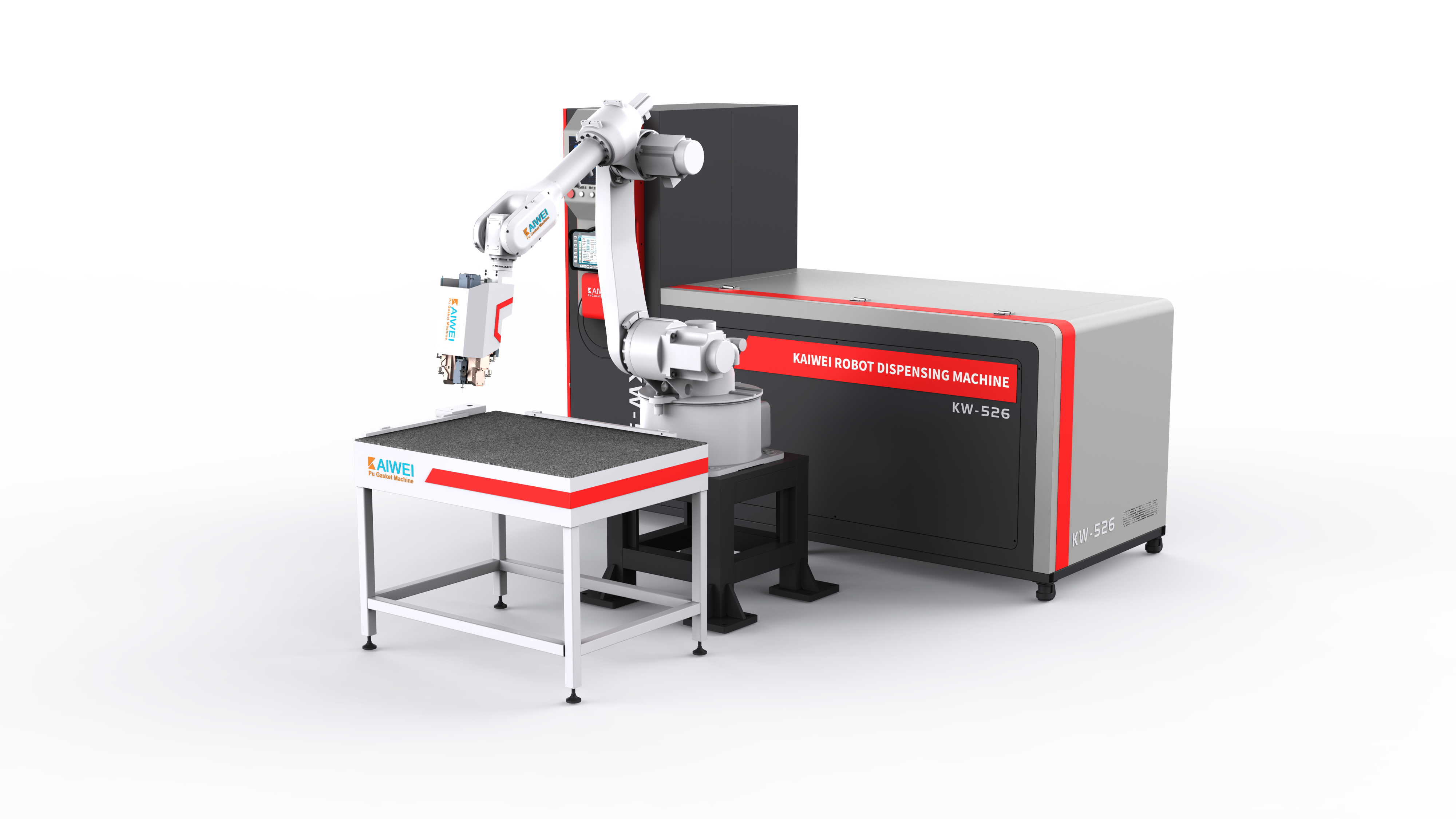

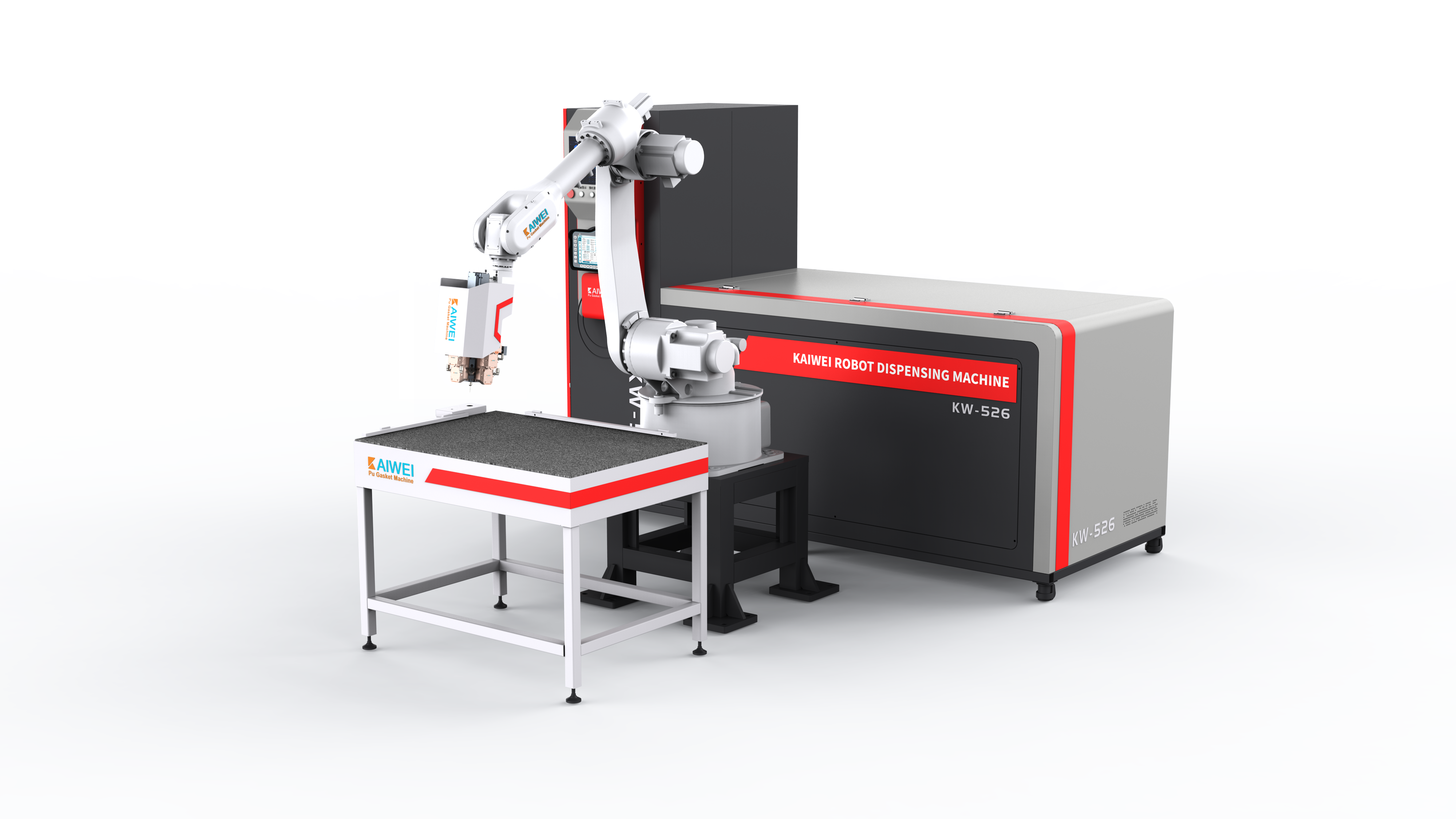

Kelincahan dan Adaptabilitas Luar Biasa

Versatilitas luar biasa yang dibangun ke dalam setiap mesin foaming pu yang dijual memungkinkan produsen menghasilkan berbagai macam produk busa menggunakan satu peralatan, memaksimalkan pengembalian investasi sekaligus meminimalkan kebutuhan ruang lantai. Adaptabilitas ini berasal dari kemampuan mesin untuk menangani berbagai formulasi poliuretan, mulai dari busa struktural kaku yang digunakan dalam aplikasi konstruksi hingga busa fleksibel untuk produk kenyamanan dan bantalan. Ruang pencampuran yang dapat disesuaikan menerima berbagai ukuran batch, memungkinkan fleksibilitas produksi yang berkisar dari produksi prototipe skala kecil hingga operasi manufaktur berskala besar. Penyesuaian rasio komponen memungkinkan pembuatan busa dengan sifat sangat berbeda, termasuk variasi kepadatan dari material insulasi ringan hingga komponen struktural berkepadatan tinggi. Sistem pemanas menyesuaikan diri terhadap berbagai kebutuhan formulasi, menjaga suhu pemrosesan optimal untuk berbagai sistem kimia dan profil curing. Kompatibilitas cetakan mencakup berbagai industri, dengan mesin foaming pu yang dijual menerima cetakan otomotif, furnitur, konstruksi, dan kemasan standar tanpa modifikasi. Sistem dispensing menyesuaikan laju alir dan pengaturan tekanan untuk mengakomodasi metode aplikasi yang berbeda, baik itu pour-in-place, injection molding, maupun proses produksi kontinu. Kemampuan pencocokan warna memungkinkan pewarnaan yang konsisten antar run produksi, penting untuk aplikasi yang terlihat di mana konsistensi estetika menjadi perhatian. Perangkat lunak mesin mendukung penyimpanan resep tanpa batas, memungkinkan produsen menyimpan perpustakaan formulasi terbukti untuk pelanggan atau aplikasi yang berbeda. Fitur pergantian cepat meminimalkan waktu henti saat beralih antar produk, dengan siklus pembersihan otomatis yang secara efisien menyiapkan sistem untuk formulasi berbeda. Penyesuaian produksi musiman menjadi lancar, karena mesin foaming pu yang dijual menyesuaikan diri terhadap kondisi lingkungan dan sifat bahan baku yang berubah akibat fluktuasi suhu dan kelembapan. Arsitektur yang dapat diperluas memungkinkan peningkatan dan fitur tambahan di masa depan, memastikan peralatan tetap relevan seiring dengan perkembangan kebutuhan bisnis. Kebutuhan pelatihan tetap minimal berkat desain antarmuka yang intuitif, memungkinkan operator menguasai berbagai lini produk dengan cepat dan efisien.