Pemahaman tentang Peralatan Mesin Penyegel Busa

Komponen Utama dan Operasi

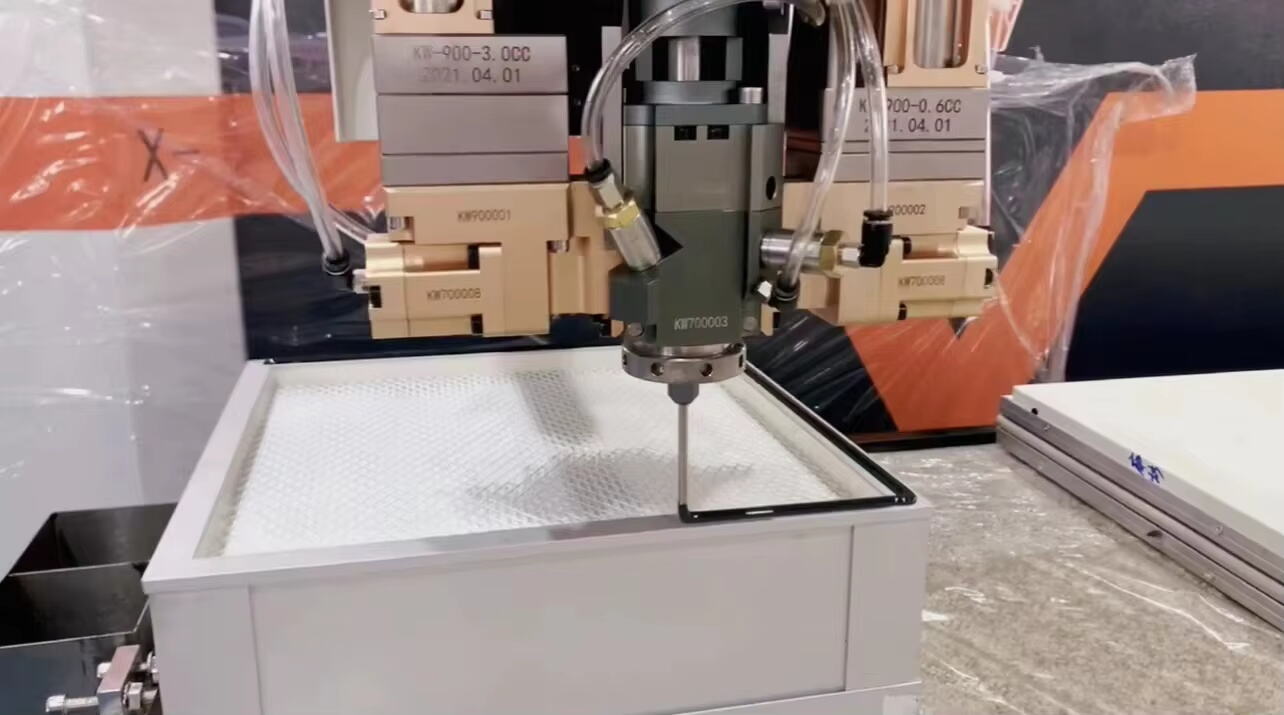

Mesin sealing foam memiliki beberapa bagian utama yang bekerja sama sehingga seluruh proses sealing berjalan lancar. Yang terpenting adalah ruang pencampuran yang mencampurkan bahan-bahan kimia secara tepat untuk menghasilkan foam berkualitas tinggi setiap saat. Selanjutnya adalah nozzle pengeluaran yang bertugas mengaplikasikan foam ke permukaan yang perlu disegel. Nozzle ini biasanya dapat disesuaikan tergantung jumlah foam yang dibutuhkan dan jenis pekerjaannya. Operator juga sangat mengandalkan panel kontrol karena bagian ini memungkinkan mereka memantau seluruh proses produksi dan melakukan penyesuaian bila diperlukan. Tanpa kontrol yang tepat, hasil yang konsisten hampir mustahil dicapai pada berbagai aplikasi yang berbeda.

Ketika semua bagian ini bekerja sama, mereka menciptakan operasi yang jauh lebih halus di mana kecepatan dalam menyelesaikan tugas menjadi sangat penting. Melihat angka-angka aktual dari lapangan memberi tahu kita seberapa baik mesin sealing foam saat ini sebenarnya. Penelitian menunjukkan bahwa pabrik-pabrik yang menggunakan mesin ini mengalami peningkatan produktivitas sekaligus mengurangi pemborosan material berkat fitur otomasi yang lebih baik dan kontrol yang lebih cerdas yang terintegrasi dalam sistem tersebut. Itulah sebabnya banyak produsen beralih menggunakan teknologi sealing foam jika mereka ingin tetap kompetitif dan menjalankan operasional pada tingkat yang lebih tinggi secara keseluruhan.

Jenis-Jenis Mesin Penyegel Busa

Terdapat beberapa jenis mesin penyegel busa yang berbeda di pasaran, dirancang untuk berbagai situasi dan tingkat kompleksitas manufaktur. Secara umum kita mengenal tiga kategori utama: unit manual, sistem semi-otomatis, dan versi sepenuhnya otomatis. Mesin manual bekerja paling baik ketika seseorang perlu menangani produksi dalam jumlah kecil atau pekerjaan khusus di mana kustomisasi menjadi prioritas utama. Mesin ini memberikan operator kontrol yang besar namun jelas membutuhkan pekerja yang memahami pekerjaannya. Peralatan semi-otomatis berada di tengah-tengah antara kedua ekstrem tersebut. Sangat cocok untuk produksi berskala menengah, peralatan ini menawarkan sebagian otomatisasi tanpa sepenuhnya menggantikan keterlibatan manusia. Dan terakhir ada mesin sepenuhnya otomatis yang pada dasarnya merupakan mesin andalan untuk operasi berskala besar. Mesin-mesin tangguh ini dapat beroperasi tanpa henti menangani volume produksi masif sambil menjaga konsistensi kualitas pada setiap unit yang diproduksi.

Model-model yang berbeda bekerja lebih baik untuk pekerjaan yang berbeda tergantung pada seberapa banyak produk yang harus dibuat dan seberapa rumit konfigurasinya. Lihat apa yang terjadi di berbagai pabrik saat ini—mesin penyegel busa otomatis sedang cepat berkembang di kalangan produsen besar karena benar-benar meningkatkan produksi sekaligus mengurangi biaya operasional. Angka-angka ini mendukung hal tersebut; banyak pabrik telah melihat peningkatan signifikan setelah beralih ke sistem otomatis. Perusahaan-perusahaan juga tidak hanya mengejar efisiensi demi kesenangan belaka. Dengan persaingan yang semakin ketat hari demi hari, pemasangan mesin-mesin tersebut merupakan langkah bisnis yang masuk akal jika mempertimbangkan penghematan jangka panjang dan perbaikan kontrol kualitas.

Industri Utama yang Menggunakan Mesin Sealing Busa

Aplikasi industri otomotif

Mesin penyegel busa memainkan peran besar dalam mobil dalam hal mengurangi kebisingan dan getaran yang tidak diinginkan yang benar-benar memengaruhi kenyamanan berkendara di dalam kabin. Saat merakit komponen seperti jendela mobil, panel pintu, dan bagian kabin, alat khusus ini mengaplikasikan bahan segel secara tepat setiap saat. Mesin ini menciptakan penghalang yang kuat untuk menghalangi masuknya angin, hujan, dan kebisingan jalan ke dalam area penumpang. Pengendalian suara yang lebih baik berarti pengemudi dan penumpang menikmati perjalanan yang lebih tenang secara keseluruhan. Selain itu, produsen harus memenuhi persyaratan tertentu yang ditetapkan oleh regulator terkait kemampuan kendaraan dalam menghalangi suara dari luar serta ketahanannya terhadap keausan normal. Perusahaan otomotif sangat mengandalkan teknologi ini karena tanpa penyegelan yang tepat, mobil akan jauh kurang menarik bagi pembeli yang mencari kabin yang tenang sekaligus konstruksi yang tahan lama.

Konstruksi dan Sistem HVAC

Mesin penyegel busa telah menjadi alat penting dalam pekerjaan konstruksi, terutama ketika mengisi celah antara material isolasi dan penghalang udara. Hal ini membantu bangunan menjadi lebih hemat energi sekaligus meningkatkan daya tahan secara keseluruhan. Ketika struktur disegel dengan baik, bangunan lebih tahan terhadap penetrasi air, yang berarti berkurangnya masalah pertumbuhan jamur dan kerusakan dinding seiring waktu. Prinsip yang sama juga berlaku pada sistem HVAC, di mana teknologi penyegelan busa digunakan secara luas untuk menyegel saluran udara dan mengisolasi berbagai komponen sistem tersebut. Menurut standar yang ditetapkan oleh organisasi seperti ASHRAE, penyegelan yang tepat dapat mengurangi pemborosan energi serta meningkatkan efisiensi sistem pemanas dan pendingin. Kontraktor yang mengikuti rekomendasi ini umumnya melihat peningkatan kenyamanan di dalam bangunan dan tagihan utilitas yang lebih rendah setiap bulannya.

Penyegelan Busa dalam Elektronik dan Mesin Industri

Perlindungan dari Faktor Lingkungan

Mesin penyegel busa sangat penting untuk menjaga komponen elektronik tetap aman dari hal-hal seperti kelembapan, debu, dan kontaminan lain yang dapat masuk ke dalam elektronik. Yang dilakukan mesin-mesin ini pada dasarnya menciptakan penghalang yang kuat di sekitar komponen agar tetap terlindungi dari hal-hal yang bisa mengganggu kinerjanya atau memperpendek usia pakainya. Komponen tanpa penyegelan yang baik cenderung lebih sering mengalami kegagalan ketika terpapar pada bahaya lingkungan tersebut. Ambil contoh kelembapan yang masuk ke dalam elektronik sensitif dan menyebabkan korsleting sehingga membutuhkan perbaikan mahal atau bahkan penggantian komponen sepenuhnya. Ketika produsen memastikan penyegelan yang tepat pada produk mereka, ini membantu keseluruhan performa menjadi lebih baik seiring waktu dan juga lebih tahan lama. Artinya pelanggan akhirnya mendapatkan peralatan yang bekerja secara andal, baik itu berada di lantai pabrik maupun di lingkungan keras di suatu tempat.

Presisi dalam Perakitan Komponen

Memastikan keakuratan dalam merakit komponen elektronik dan mesin industri sangatlah penting, dan mesin penyegel busa benar-benar menonjol berkat ketelitian dan hasil yang konsisten. Presisi menjadi faktor krusial untuk keandalan produk, terutama di sektor seperti kedirgantaraan atau perangkat medis, di mana tingkat ketelitian harus sangat tinggi. Teknologi di balik penyegelan busa telah berkembang pesat belakangan ini, memungkinkan produsen menerapkan bahan segel secara tepat pada bentuk komponen yang kompleks. Para ahli di industri yang telah kami bicarakan menyatakan bahwa perkembangan dalam teknologi penyegelan ini telah mengubah total cara pabrik merakit komponen. Dengan adanya mesin-mesin ini, perusahaan mampu mencapai target kualitas yang ketat sekaligus memastikan produk tetap utuh dan berfungsi dengan baik sepanjang masa pakainya.

Manfaat Peralatan Penyegel Busa Modern

Efisiensi dan Presisi yang Ditingkatkan

Mesin penyegel busa saat ini jauh lebih efisien dibandingkan teknik penyegelan lama. Sistem modern ini bekerja jauh lebih cepat sambil tetap andal untuk menjaga jalannya produksi tanpa gangguan berhenti yang mengganggu alur kerja. Mesin-mesin ini dirancang dengan presisi, sehingga mengurangi bahan yang terbuang selama proses berlangsung. Segel yang lebih baik berarti kualitas produk secara keseluruhan meningkat karena terjadi lebih sedikit kesalahan dalam proses produksi. Menurut beberapa data manufaktur dari beberapa tahun terakhir, perusahaan yang menggunakan teknologi penyegelan canggih mengalami peningkatan signifikan dalam kinerja operasional mereka. Inilah sebabnya mengapa banyak industri berbeda bergantung pada mesin-mesin ini ketika mereka menginginkan hasil yang konsisten tanpa mengorbankan standar kualitas.

Kestabilan dan Pengurangan Biaya

Mesin penyegel busa telah menjadi pendorong utama dalam upaya membuat proses manufaktur lebih berkelanjutan. Mesin-mesin ini mengurangi limbah material sekaligus menggunakan energi secara lebih efisien secara keseluruhan, sesuatu yang sangat dibutuhkan oleh para produsen untuk tetap kompetitif saat ini. Sebagai contoh, beberapa pabrik melaporkan pengurangan limbah material hingga lebih dari 30% setelah beralih ke sistem modern. Penghematan tidak berhenti sampai di situ saja. Ketika perusahaan mengoptimalkan penggunaan tenaga kerja dan bahan baku dengan teknologi penyegelan yang lebih baik, biaya operasional turun secara signifikan. Banyak perusahaan menemukan diri mereka menghemat ribuan dolar setiap bulannya hanya dengan pengelolaan sumber daya yang lebih cerdas. Di luar manfaat finansial, adopsi teknologi-teknologi ini membantu perusahaan mewujudkan komitmen lingkungan mereka. Industri-industri di berbagai sektor kini melihat penyegelan busa sebagai bagian penting untuk menjaga keseimbangan antara inisiatif ramah lingkungan dan margin keuntungan, membuktikan bahwa keberlanjutan tidak selalu berarti mengorbankan kinerja finansial.

Memilih Mesin Penyegel Busa yang Tepat

Menilai Kebutuhan Produksi

Memilih mesin penyegel busa yang tepat dimulai dengan mempertimbangkan kebutuhan bisnis untuk operasionalnya. Saat mencari pilihan di pasaran, produsen perlu memikirkan hal-hal seperti seberapa cepat mereka perlu memproduksi barang, berapa banyak unit yang diperkirakan perlu disegel setiap hari, serta jenis bahan yang paling sering mereka gunakan. Ambil contoh pabrik yang beroperasi penuh sepanjang hari setiap hari—mereka membutuhkan peralatan yang mampu mengikuti ritme tersebut sambil tetap menghasilkan segel berkualitas baik. Banyak perusahaan yang mendapatkan manfaat dengan melihat apa yang telah berhasil dilakukan perusahaan sejenis. Sebagian mungkin mempertimbangkan bagaimana sebuah pabrik pengemasan beralih dari sistem manual ke otomatis, atau melihat permasalahan yang dihadapi produsen lain ketika meningkatkan skala produksi. Mendapatkan informasi praktis semacam ini membantu menghindari kesalahan yang berbiaya tinggi di masa mendatang. Perusahaan yang meluangkan waktu untuk mencocokkan kebutuhan spesifik mereka dengan teknologi yang tersedia cenderung mendapatkan hasil yang lebih baik secara keseluruhan. Garis produksi mereka berjalan lebih lancar, limbah berkurang, dan biaya pemeliharaan tetap terjangkau dibandingkan dengan perusahaan yang terburu-buru membeli tanpa perencanaan matang.

Perawatan dan Nilai Jangka Panjang

Menjaga mesin sealing foam berjalan lancar sangat bergantung pada perawatan rutin. Sebagian besar operator mengetahui bahwa tugas dasar seperti membersihkan nozzle, memeriksa segel, dan mengawasi bagian yang aus dapat mencegah gangguan yang mengganggu pada saat yang tidak terduga. Perusahaan yang menghabiskan uang lebih di awal untuk mesin berkualitas baik biasanya bisa menghemat biaya dalam jangka panjang karena mesin tersebut membutuhkan sedikit perbaikan dan umumnya lebih awet. Manajer pabrik yang telah kami ajak bicara sangat mendukung pendekatan ini setelah melihat berkurangnya waktu henti (downtime) ketika perawatan tidak diabaikan. Beberapa studi menunjukkan bahwa perusahaan yang mematuhi jadwal perawatan bisa mendapatkan umur pakai peralatan sekitar 25% lebih lama sebelum harus diganti. Jadi meskipun tidak ada yang menyukai pengeluaran waktu untuk pemeriksaan rutin, hal ini benar-benar memberikan hasil dalam bentuk usia mesin yang lebih panjang dan kinerja yang konsisten seiring waktu.

Pertanyaan yang Sering Diajukan

Apa saja komponen utama mesin sealing foam?

Mesin sealing busa terutama terdiri dari ruang pencampuran, nozzle pengeluaran, dan panel kontrol. Komponen-komponen ini bekerja sama untuk memastikan pembuatan dan aplikasi busa yang efisien.

Apa manfaat mesin sealing busa bagi industri otomotif?

Di sektor otomotif, mesin-mesin ini mengurangi kebisingan dan getaran, meningkatkan insulasi, serta memenuhi standar industri untuk peredaman suara, sehingga meningkatkan kenyamanan dan kinerja kendaraan.

Apa peran mesin sealing busa dalam konstruksi dan sistem HVAC?

Mesin-mesin tersebut menyegel material insulasi dan penghalang udara untuk meningkatkan efisiensi energi dan memastikan daya tahan bangunan. Pada sistem HVAC, mesin ini membantu menginsulasi saluran udara, mencegah kebocoran udara dan meningkatkan kinerja sistem.

Bagaimana mesin sealing busa melindungi elektronik?

Mesin-mesin ini menciptakan penghalang yang melindungi komponen elektronik dari ancaman lingkungan seperti kelembapan dan debu, sehingga mengoptimalkan kinerja dan memperpanjang umur perangkat.